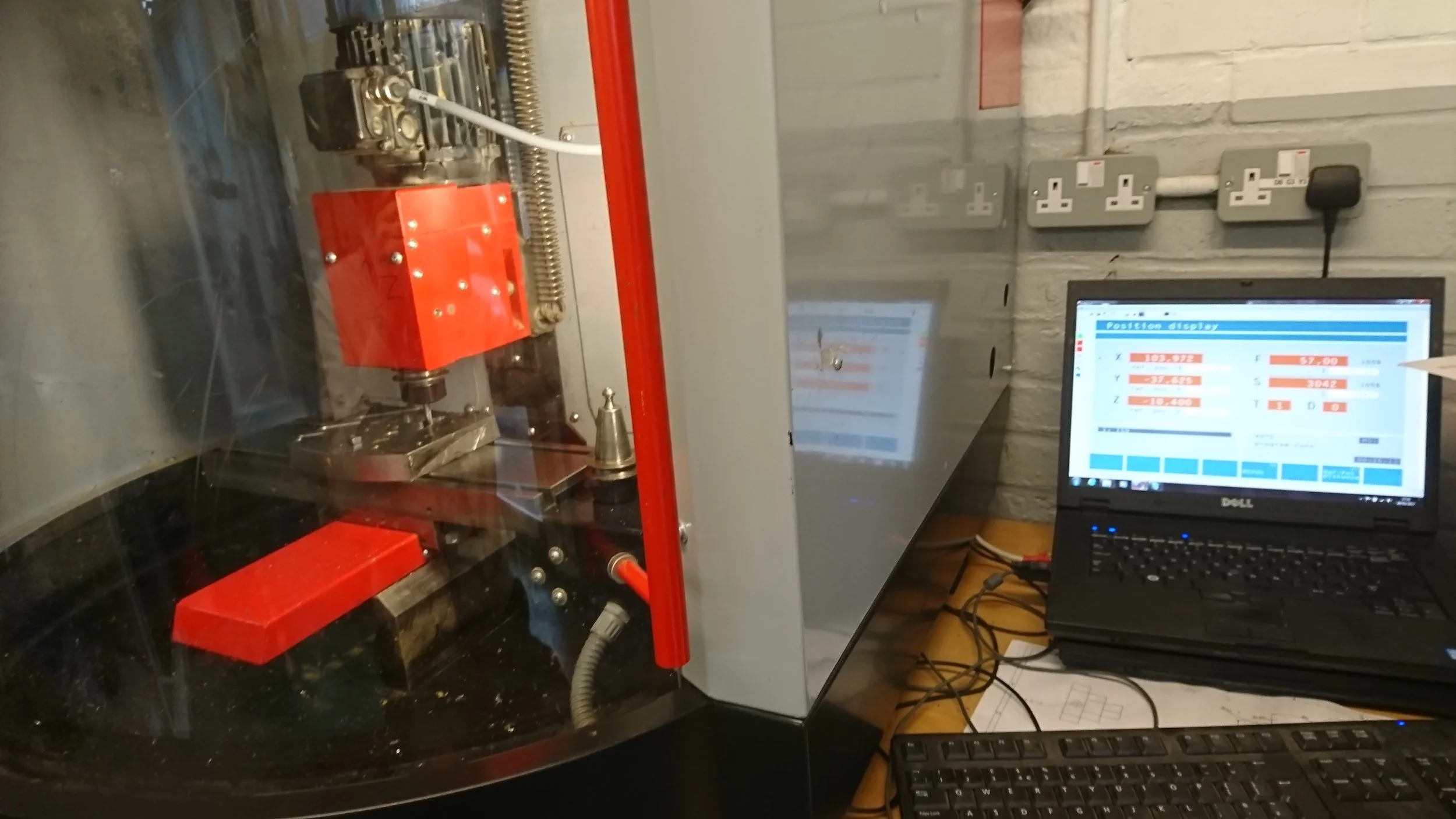

CNC Milling

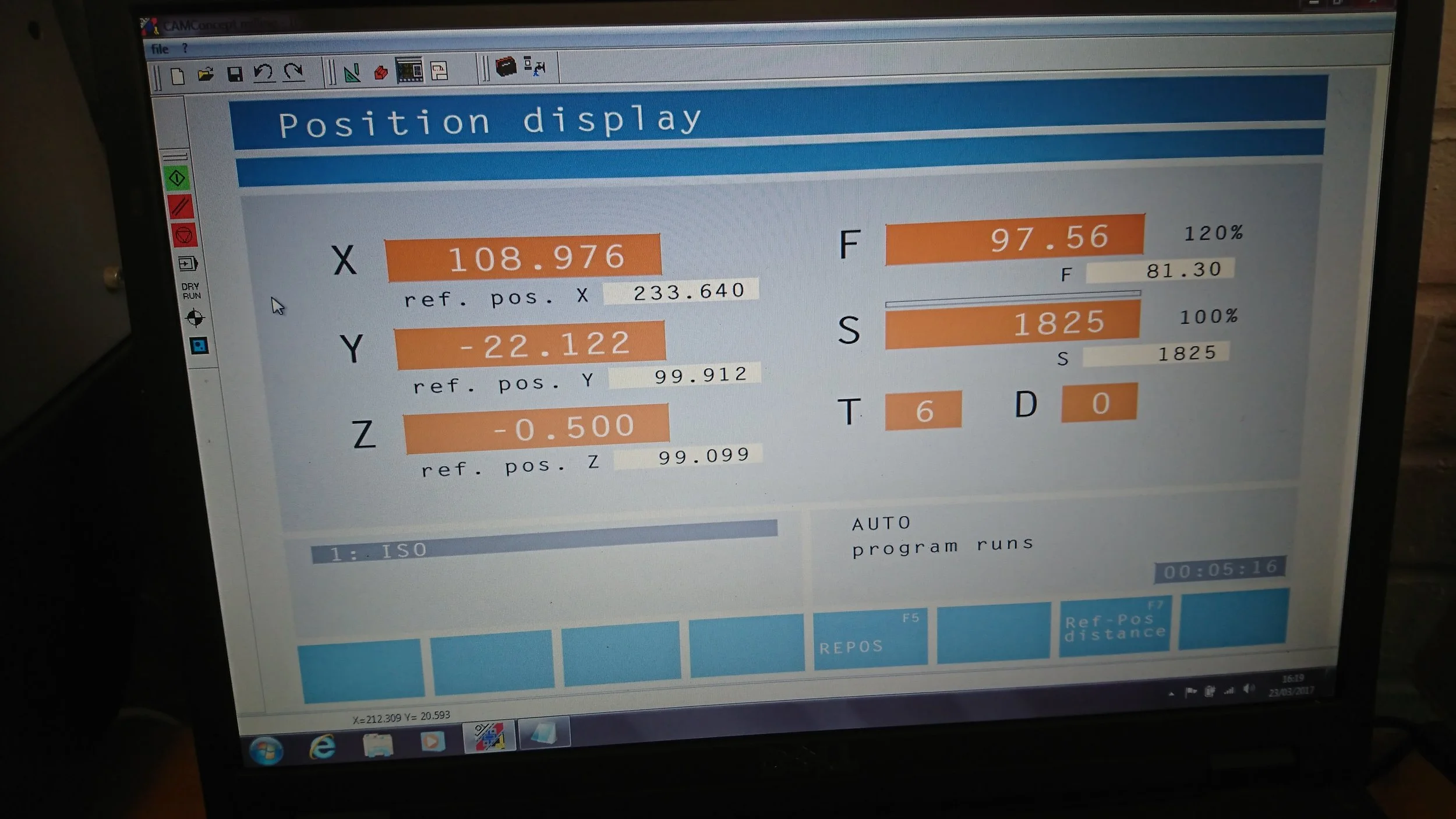

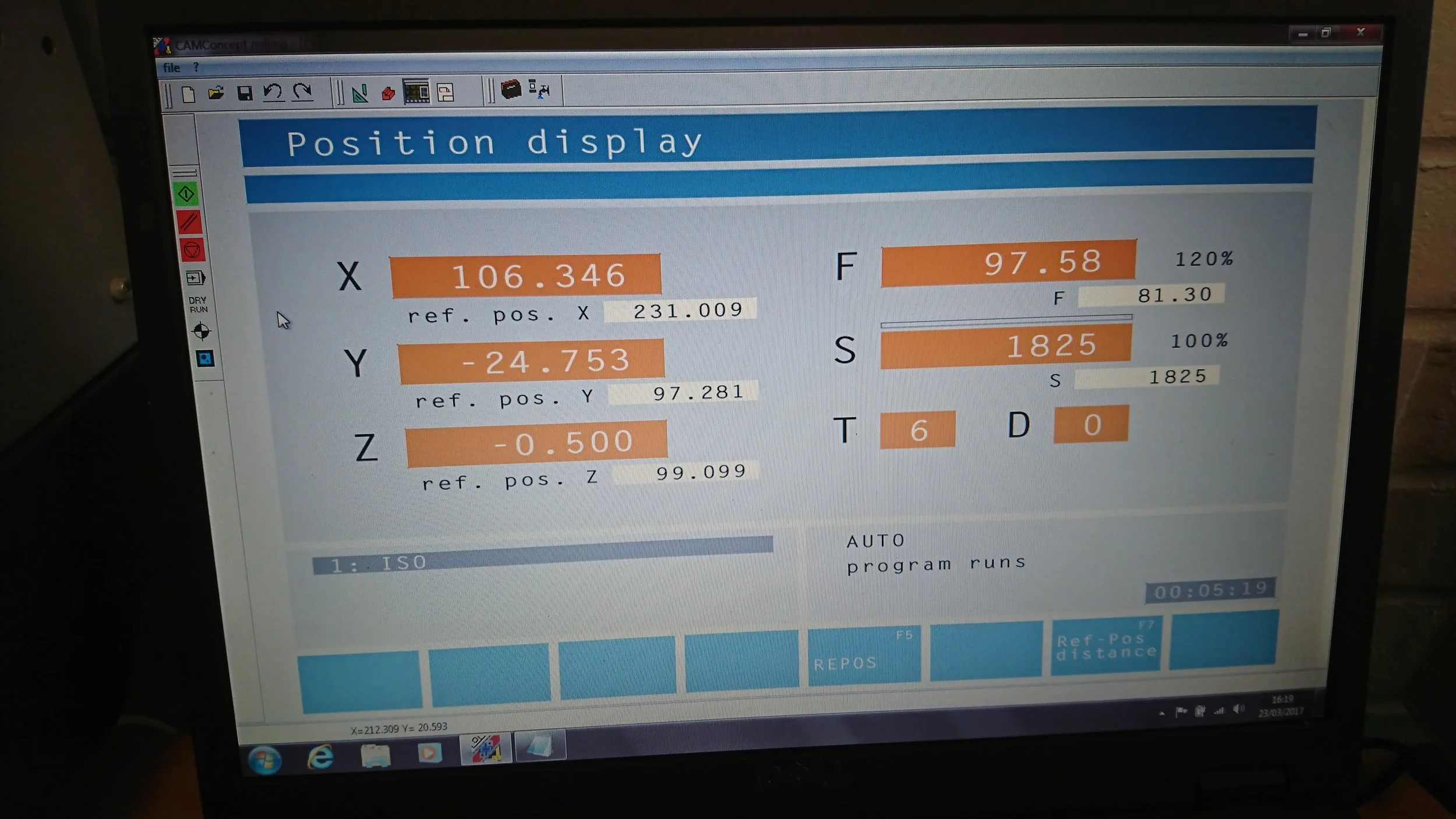

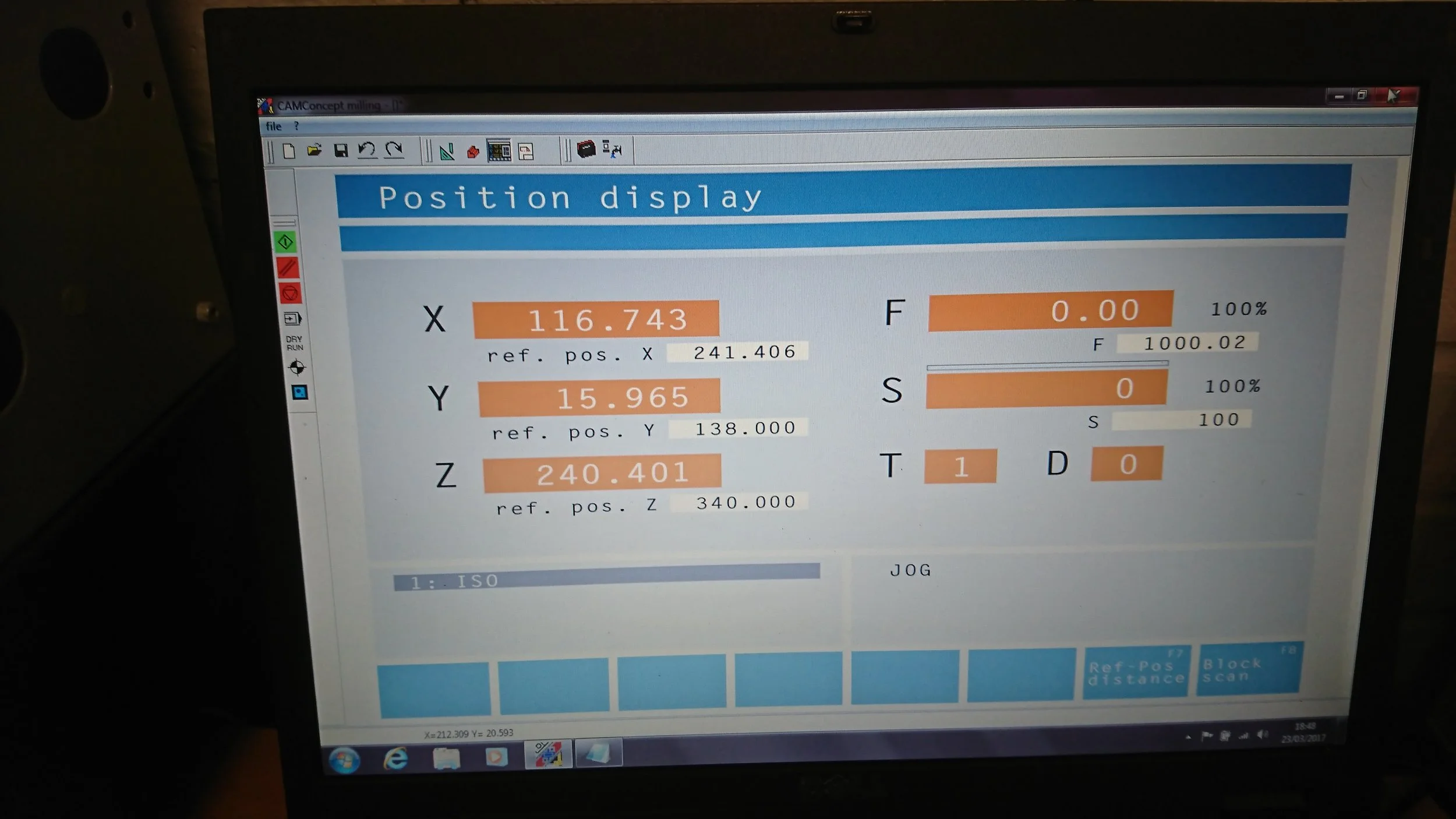

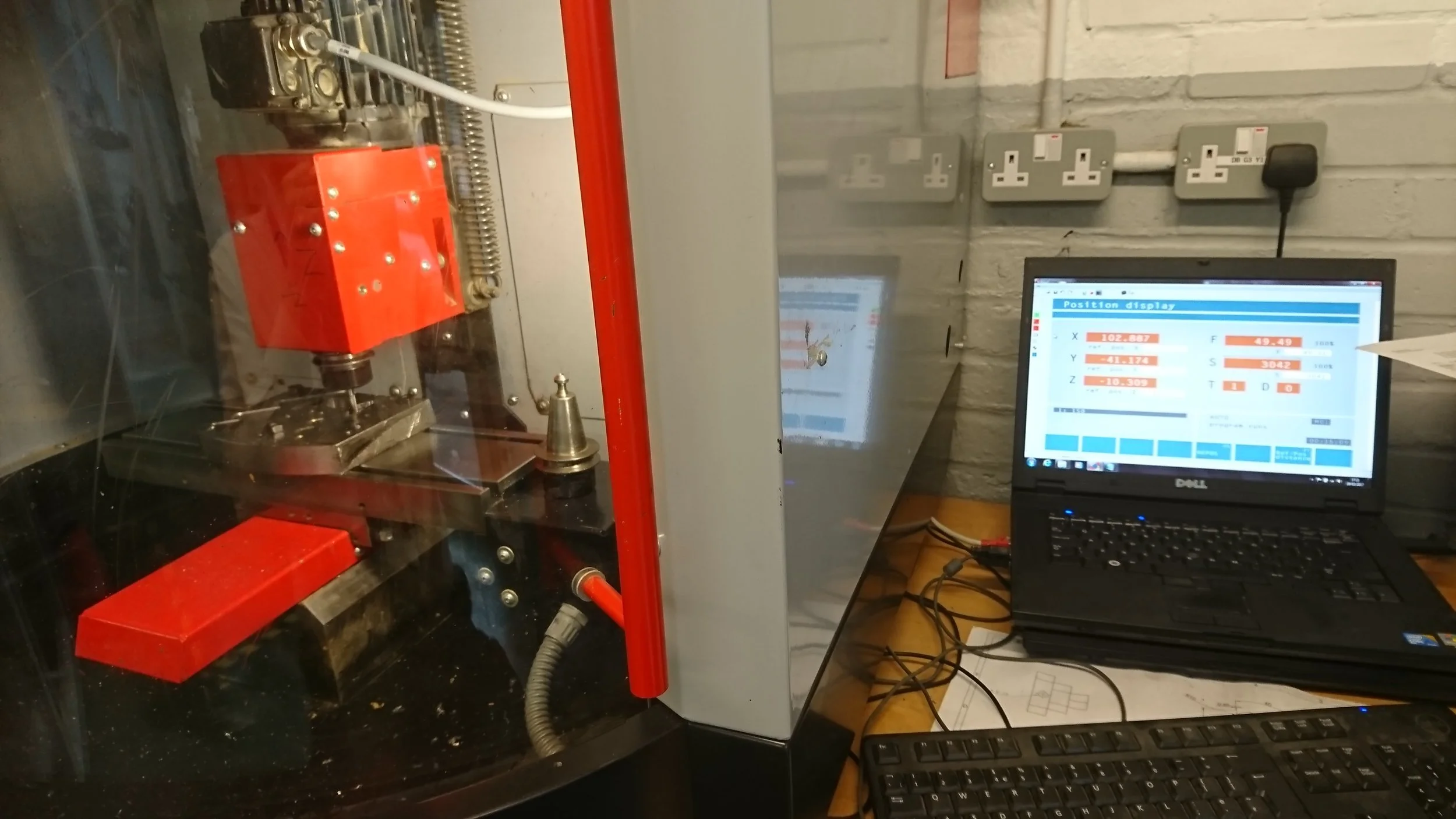

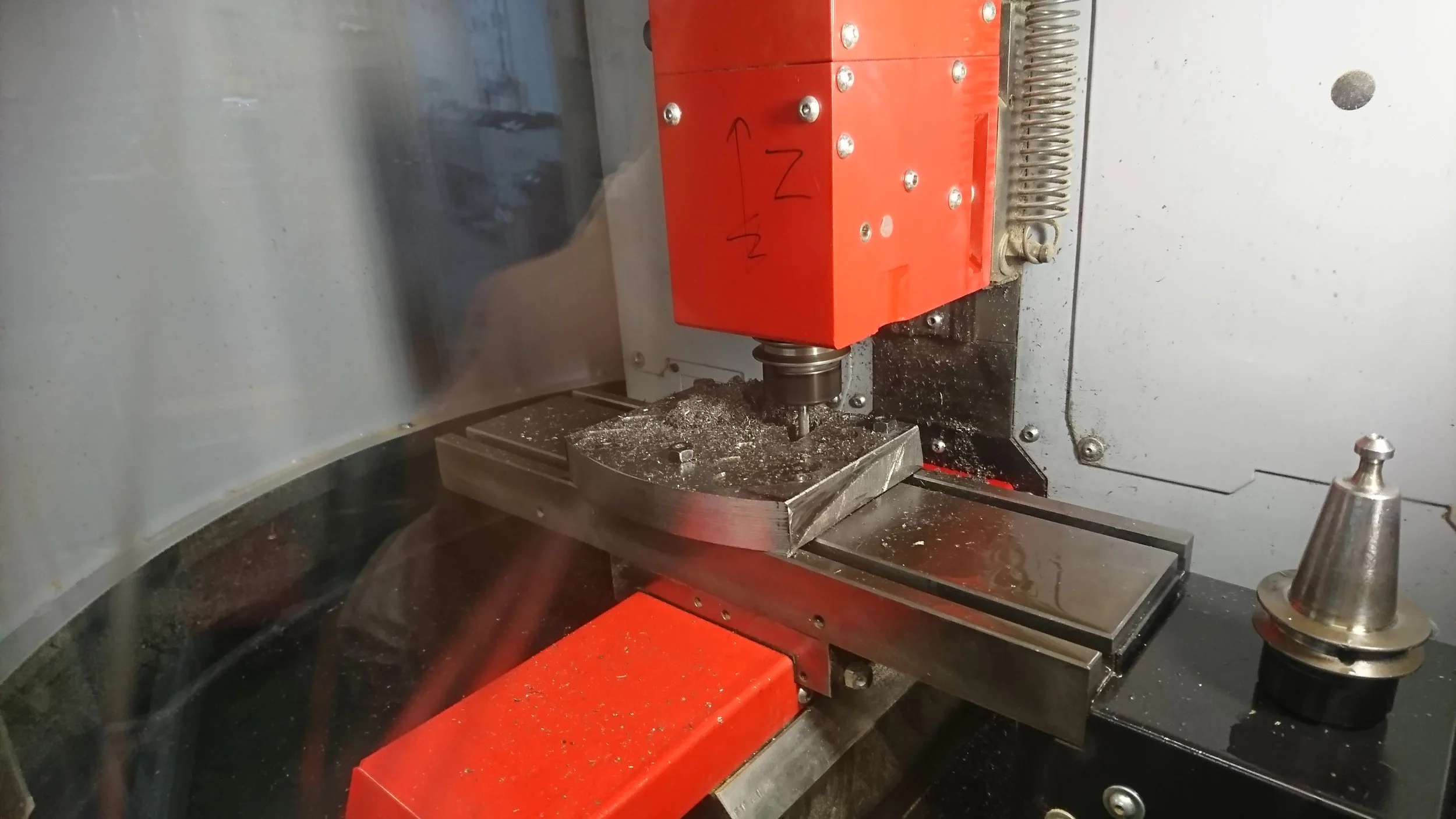

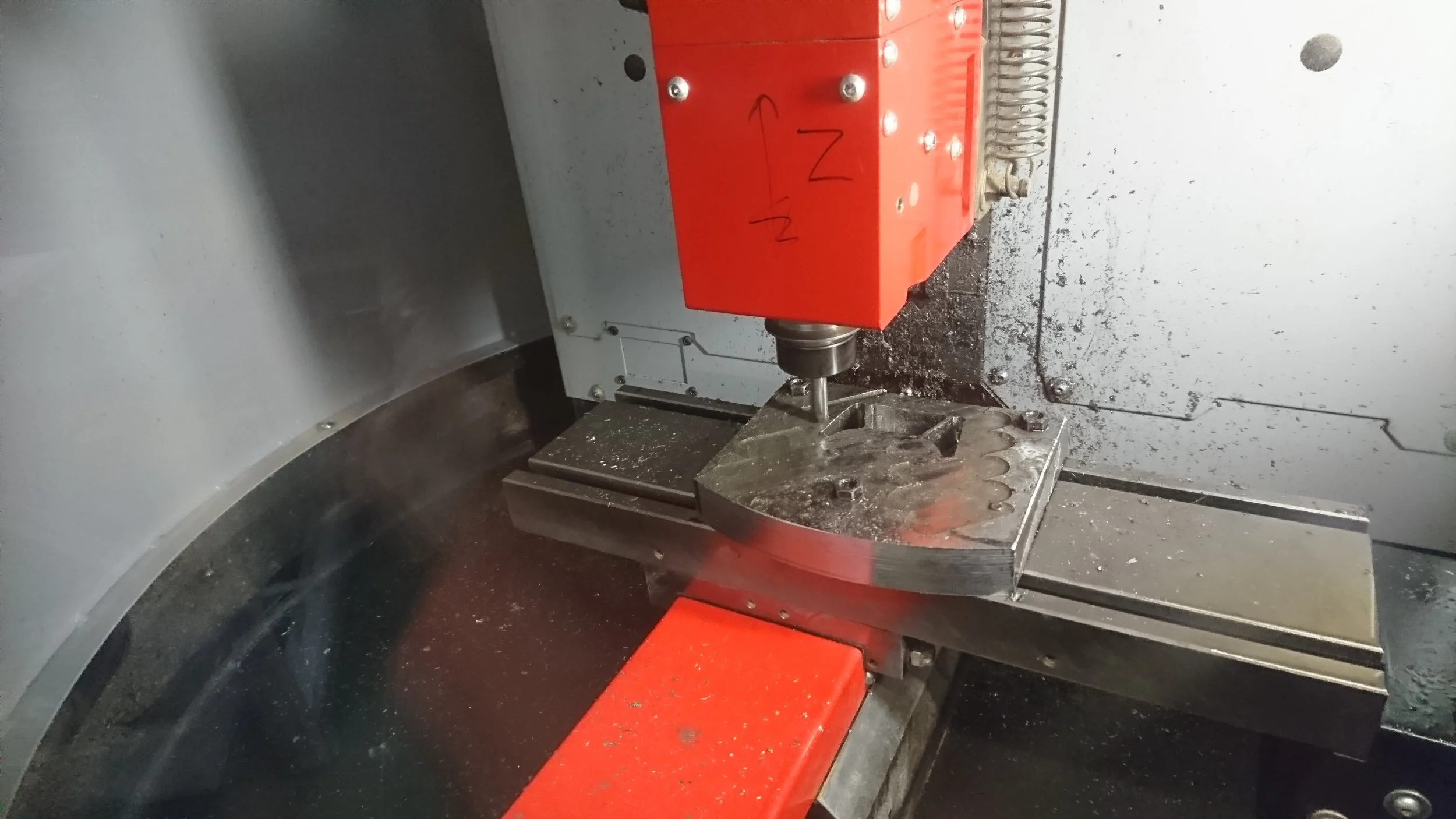

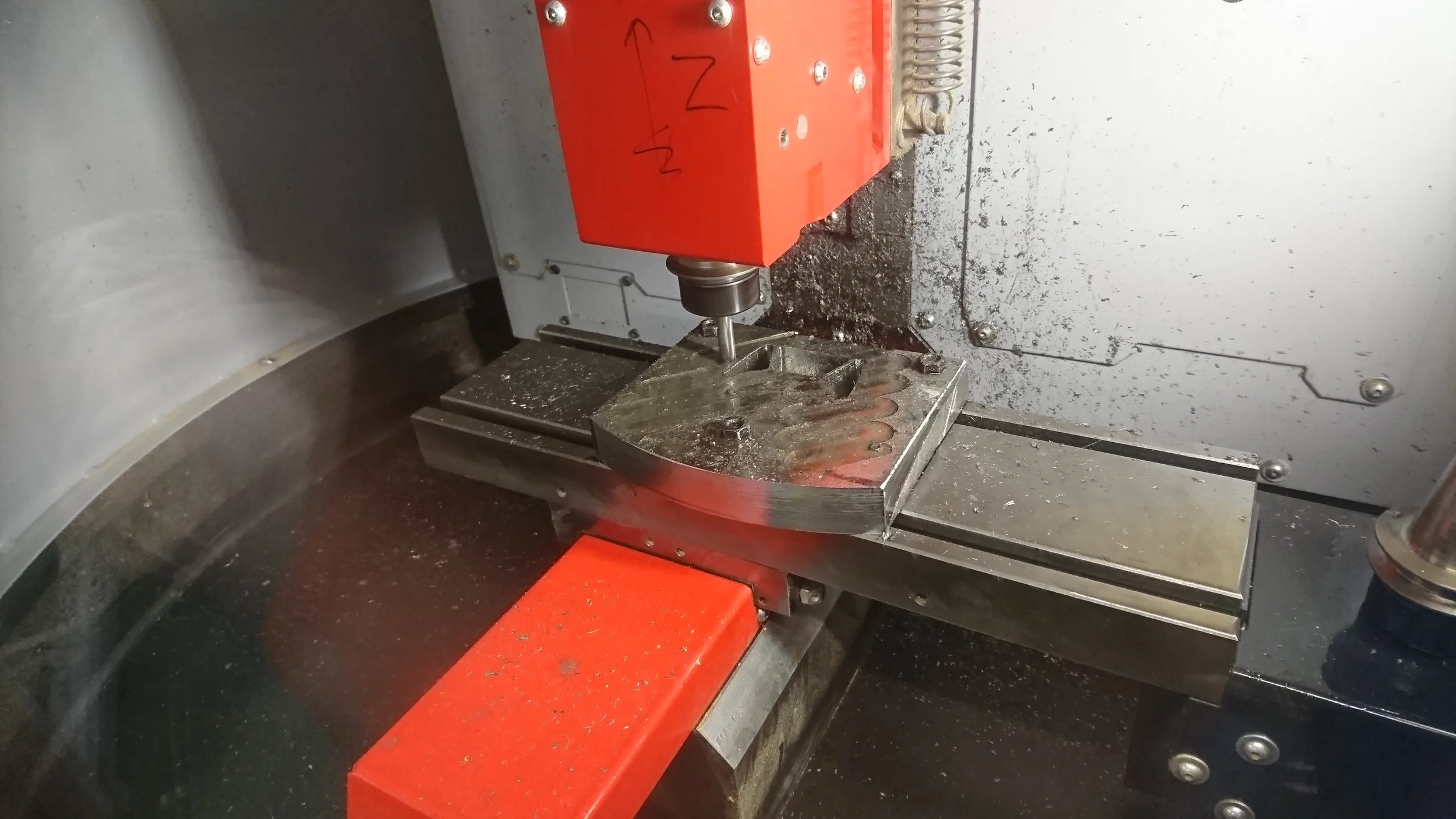

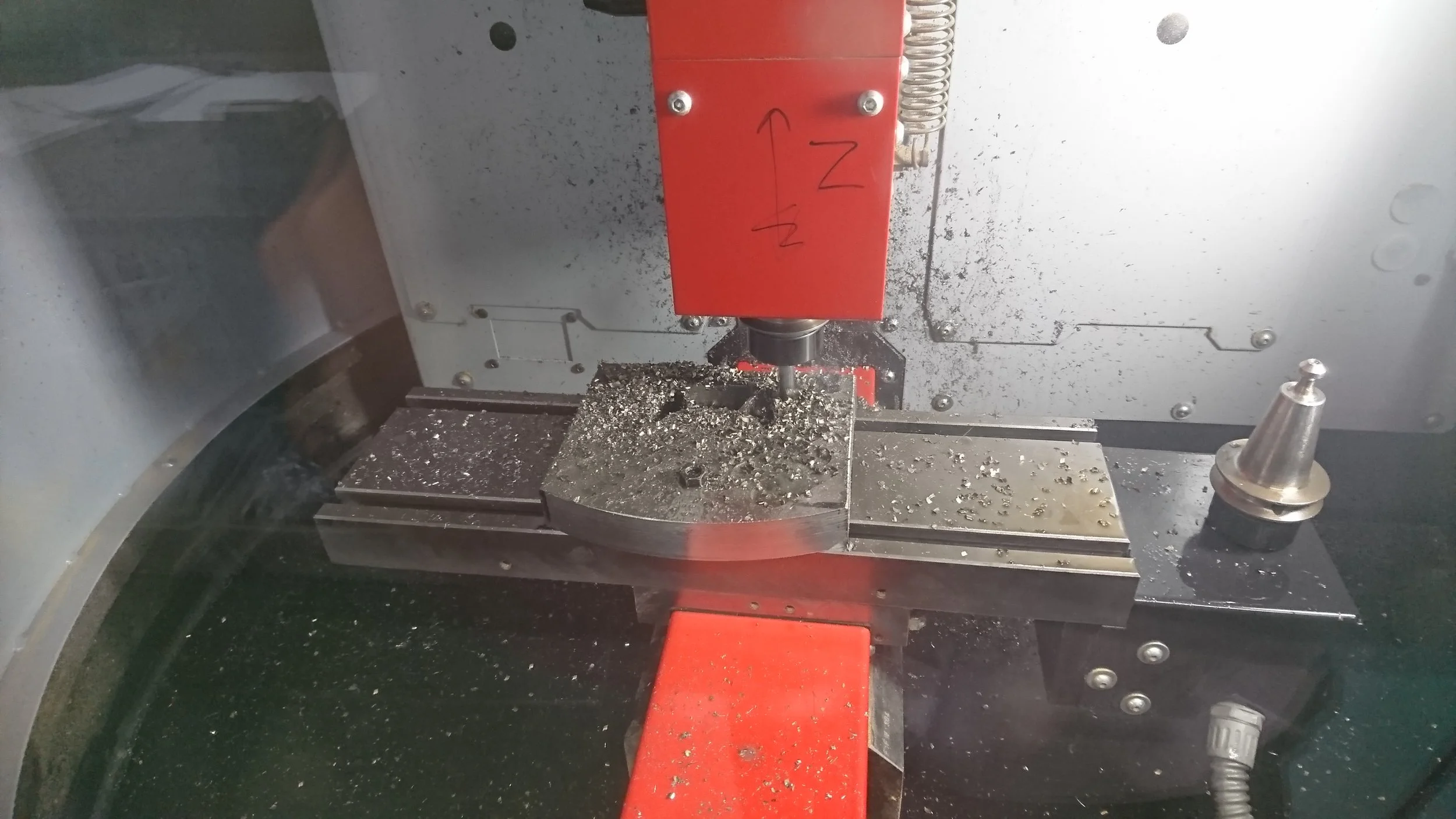

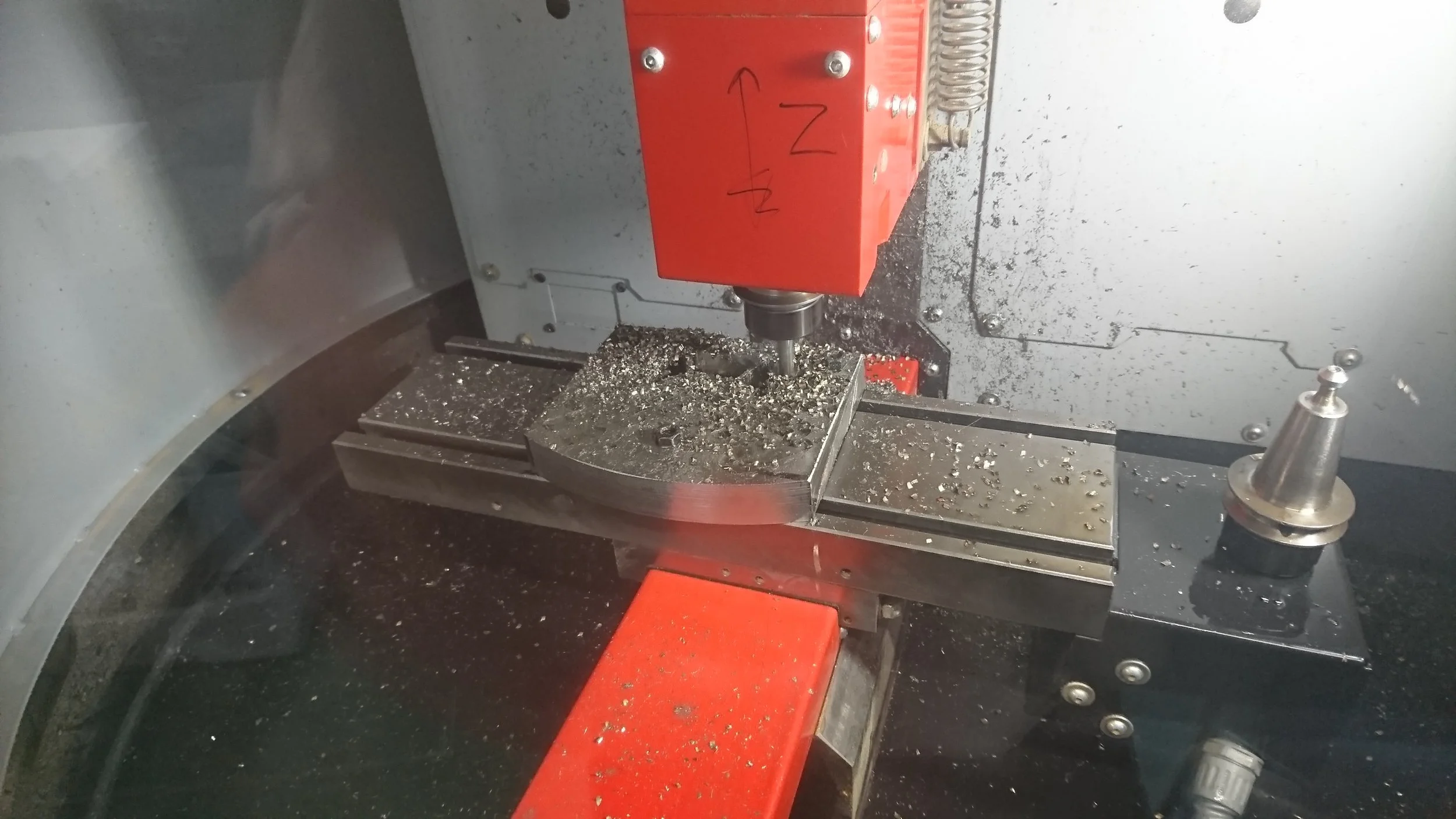

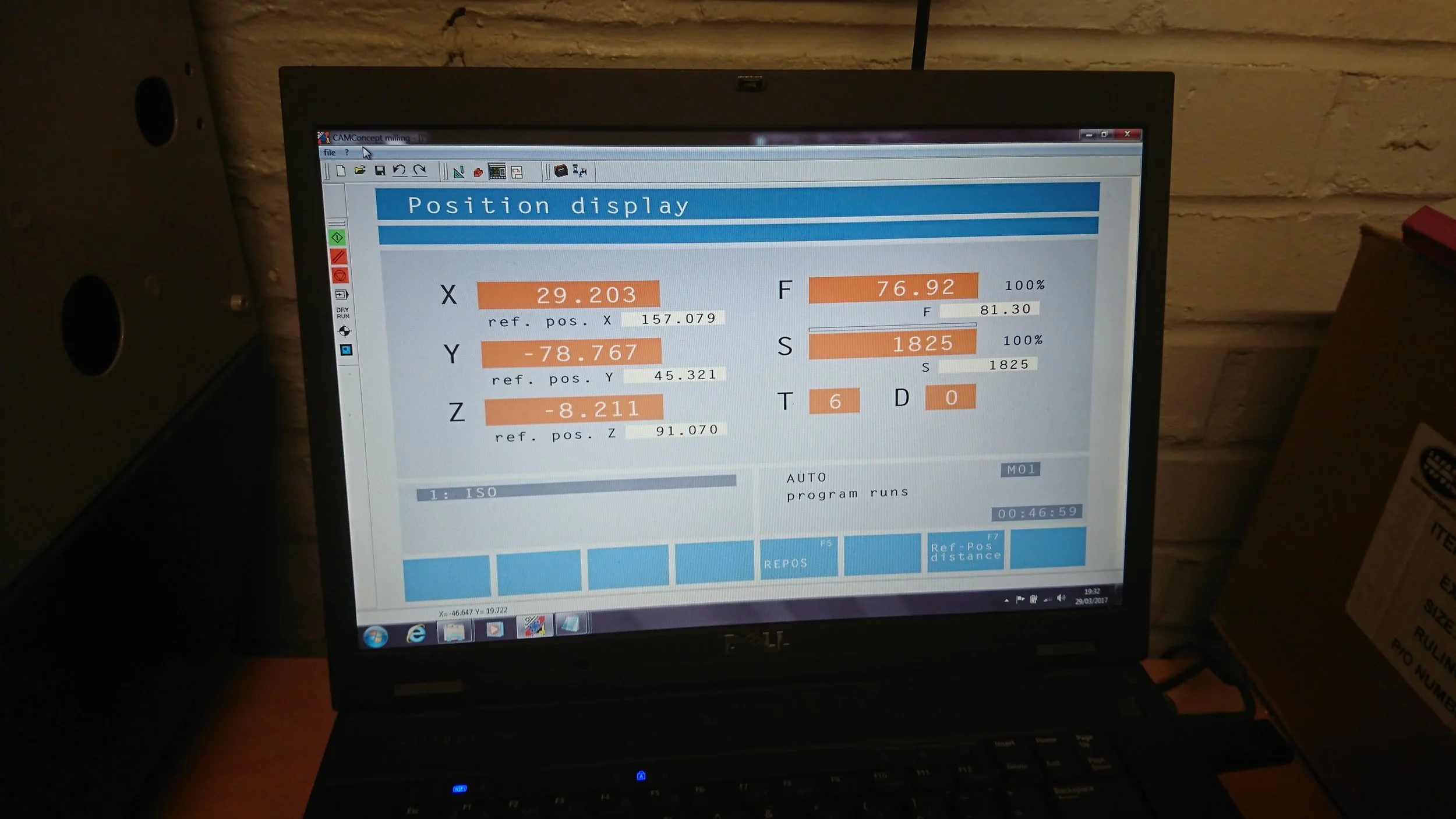

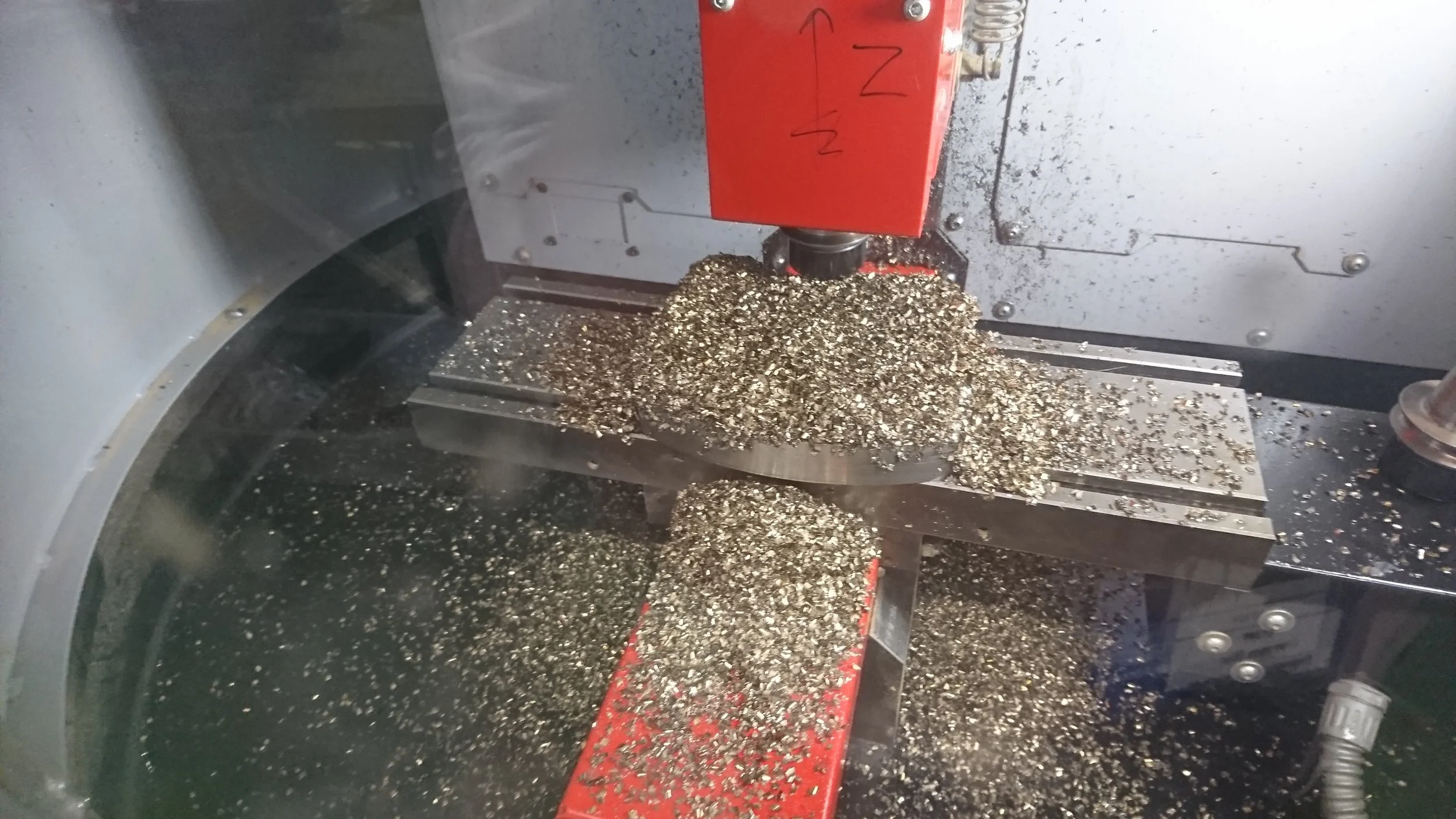

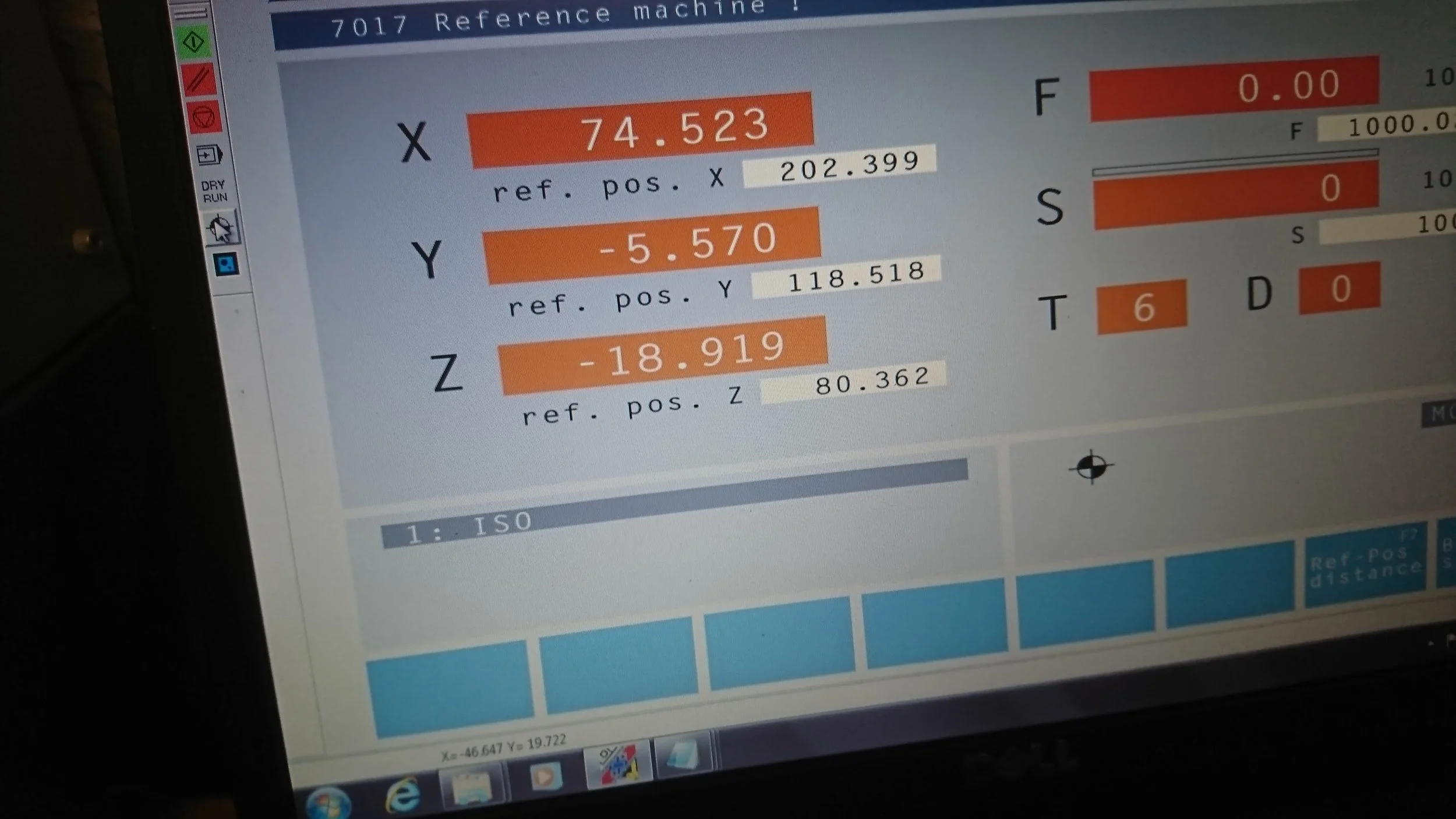

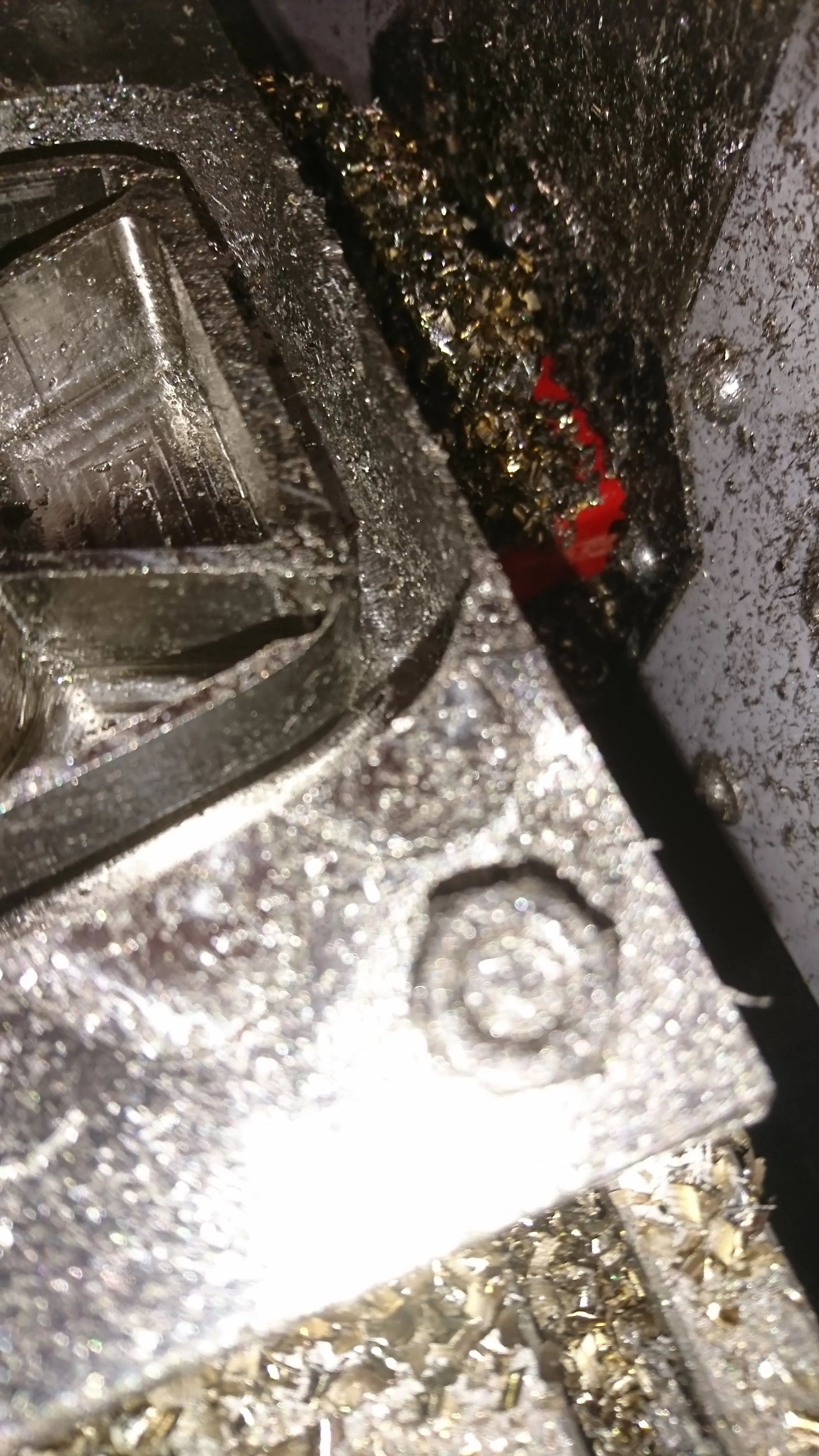

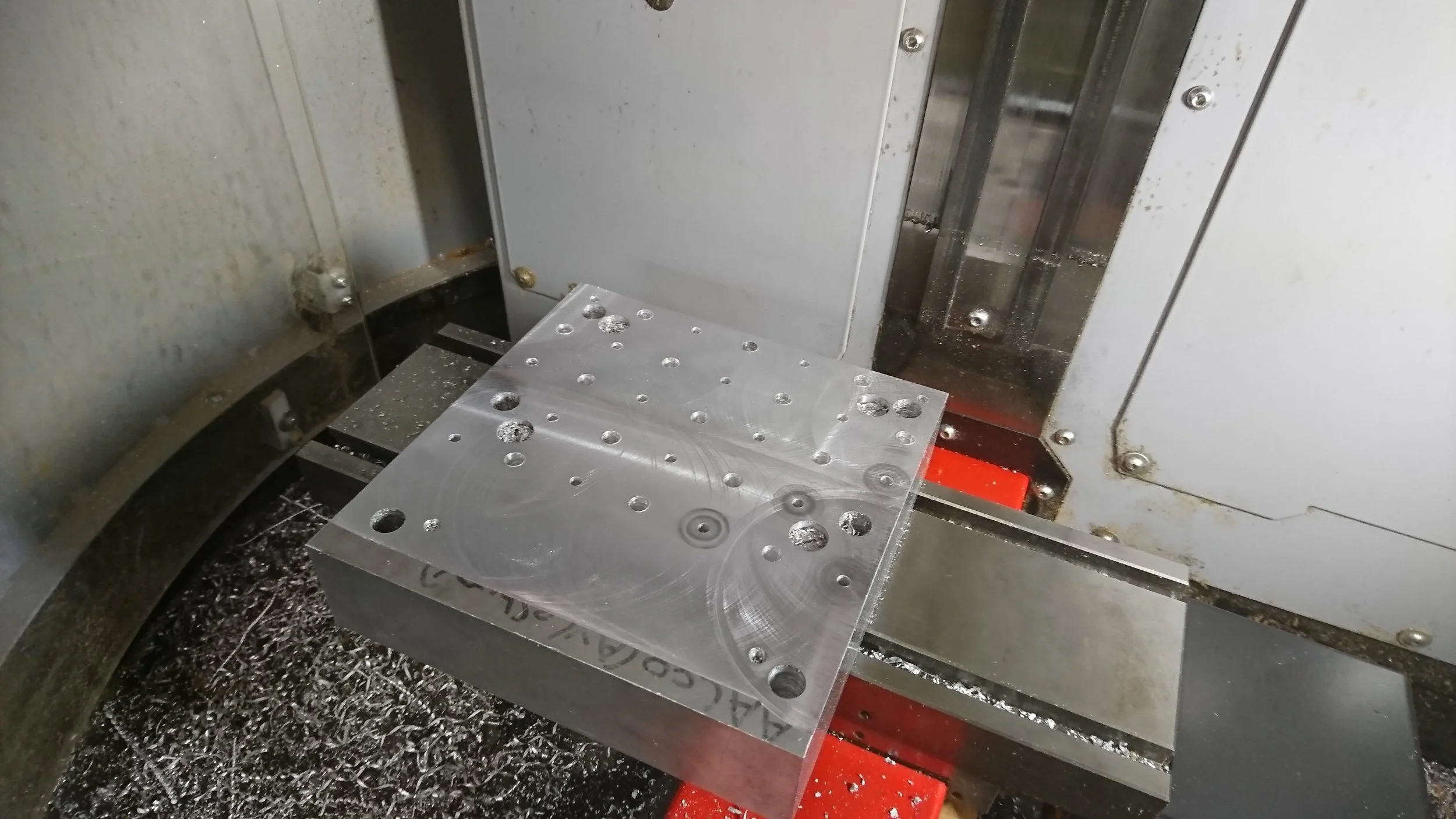

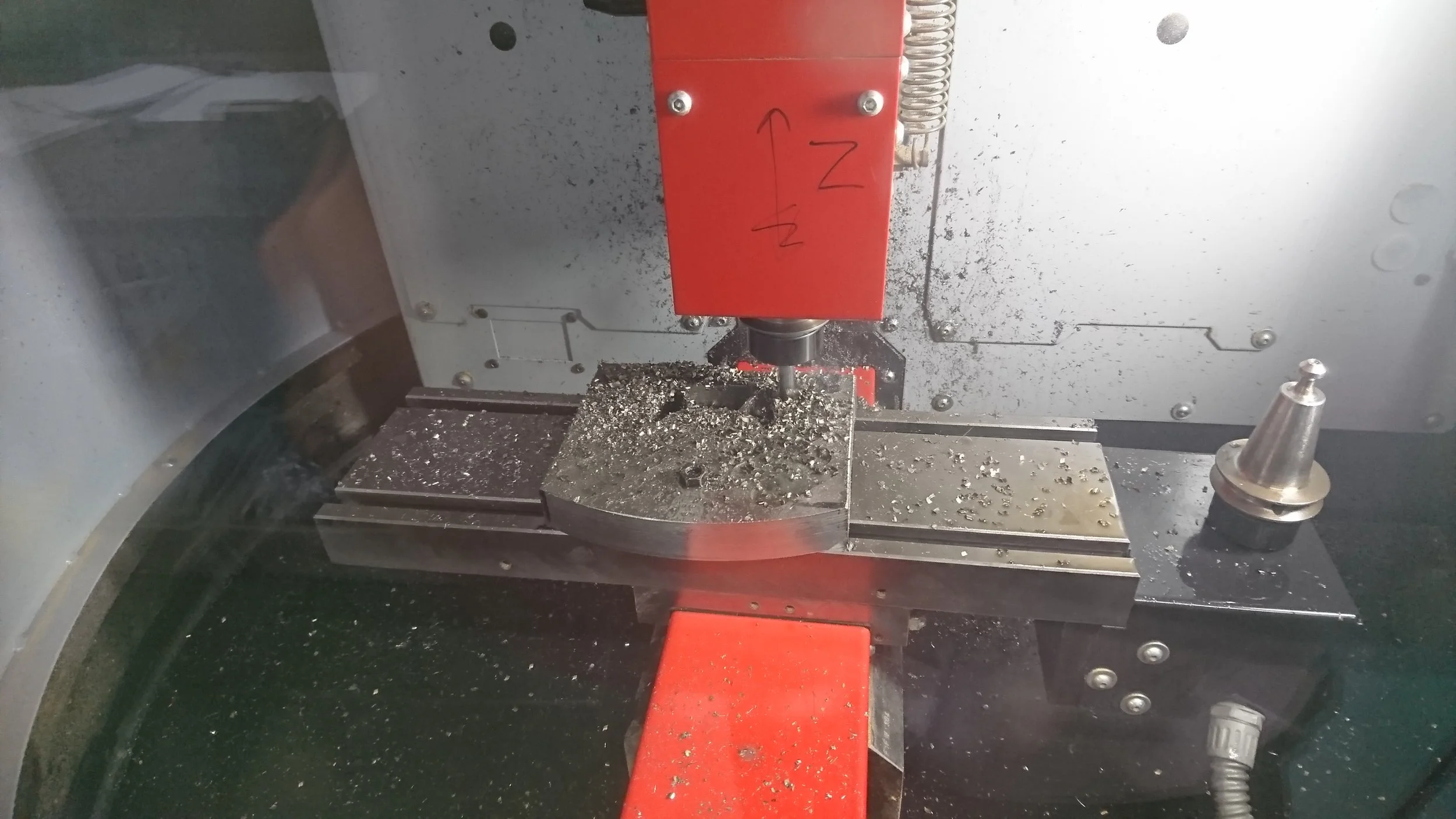

One of the first tools that I learnt to operate when I started at The Chalfonts Community College was the CNC Milling machine. This was an EMCO Concept Mill 55, a small, though well-built desktop CNC that was designed from the ground up for education. It was designed to be run using an NC emulator, allowing it to run with multiple different industry controller options, e.g. Fanuc, Siemens, Heidenhain, each for a price. Given the school environment, these options were deemed too expensive and the default EMCO CamConcept software was run, loosely based on Siemens G-code. I initially learnt to operate the machine using the canned routines in the software, but soon wanted to do more than basic 2.5d machining that I could do equally well, and mostly faster, on our manual machine. I therefore set about editing a post processor in HSM Works, which required me to get familiar with G-Code. While the process was complicated, in the end I got a post processor that worked reasonably consistently and allowed me to do full 3-axis milling, producing compound curves in 3 axes and enabling me to convert SolidWorks drawings into real parts, in all sorts of materials, from polymers and wood to non-ferrous and even ferrous metals. I found G-Wizard helped me to select feeds and speeds. I have run demonstrations and produced components on this machine and the CNC Lathe (Concept Turn 55) that lived alongside it.