Display Boards

I have produced numerous display boards for the Technology department at The Chalfonts Community College. These have included displays on CAD and CAM, Materials used in Technology as well as corridor displays showing career pathways, student projects, course outlines and more. I have tried to use my creativity to create eye catching and informative displays, often including 3D elements that demonstrate processes and techniques utilised in the subject.

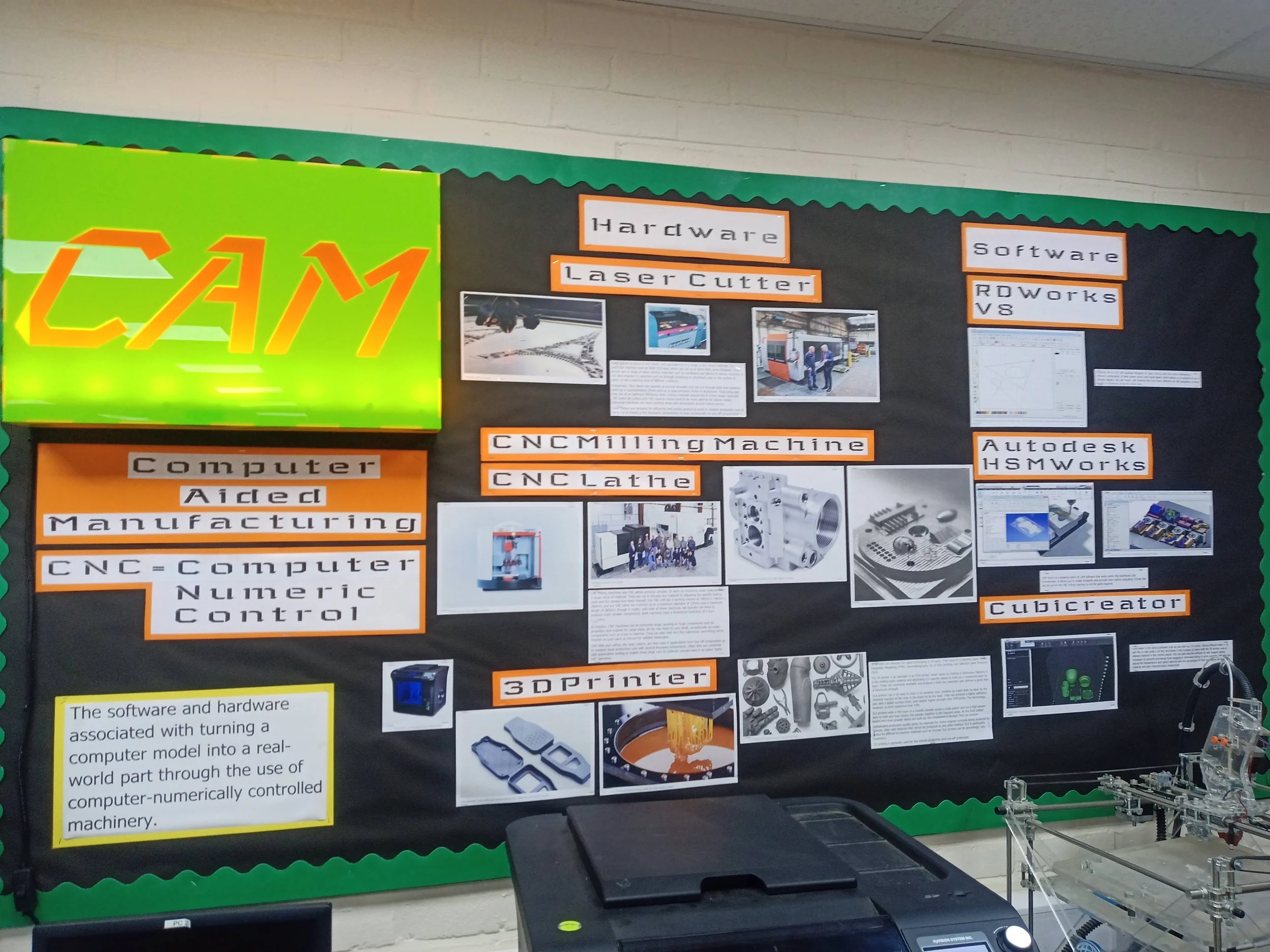

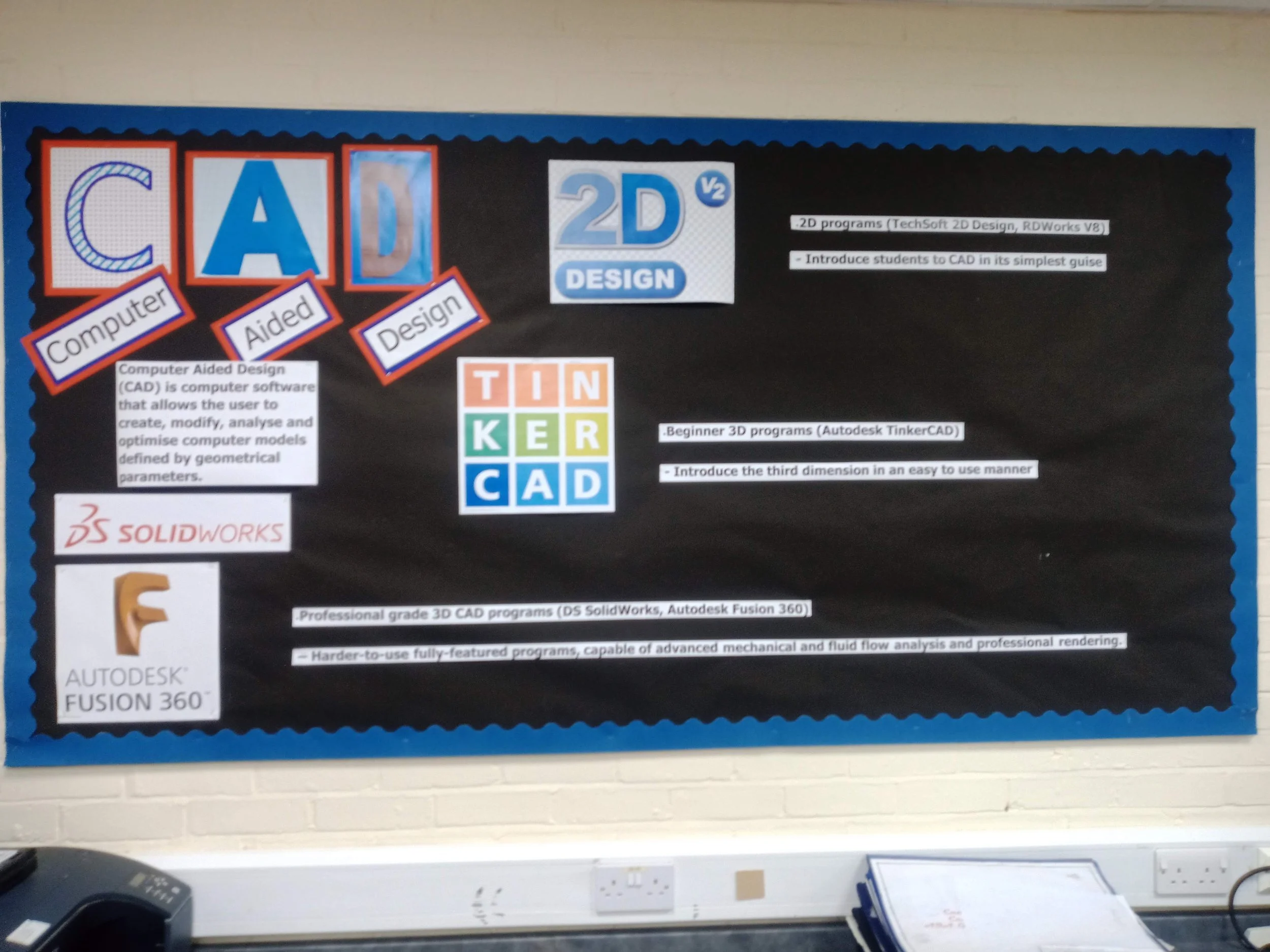

This corner used to be particularly dull with dated displays. We decided to turn the area into a CAD/CAM corner, with 3D printing and laser cutting, with a vinyl printer/cutter to be added later. I designed and produced these two display boards, showcasing and informing about these techniques.

This CAM board featured an LED lit sign, laser cut from acrylic. A large aluminium heatsink kept the temperatures down from these super bright LEDs and a mains power supply/transformer was used to power them. Each CAM process features images and interesting information about the use of CAM techniques in industry.

The CAD board displayed some different CAD designed letters forming the title. Different CAD packages that were in use at the department at that particular point in time were then detailed below. This has been updated as required as the CAD packages in use have changed.

Asked to produce a display showing different materials used in Design & Technology, I made a centrepiece title that used a whole range of different material examples.

The top three letters represent Wood: manufactured boards represented by oriented strand board (OSB), hardwoods, represented with Walnut and softwood, represented by pine.

The middle three letters represent metals: non-ferrous metals represented by copper, ferrous metals represented by stainless steel and alloys, represented by brass..

The lower three letters represent plastics: thermoset polymers and composites represented by carbon fibre reinforced polymer, thermoplastic synthetic polymers represented by High Density Polystyrene (HDPS) and natural polymers, represented by natural rubber.

I also used numerous processes and finishing techniques, including staining, waxing and varnishing, copper beating, engine turning and TIG welding, polishing and solid rivetting, composite hand layup, vacuum forming and hand engraving.

This title formed the centrepiece of the display, here pictured mounted before the supporting information was added.

Gradually adding information outlining different materials, their properties and uses, all grouped by category.

Woods and metals are shown to the left of the title.

Polymers and composites are to the right of the title.