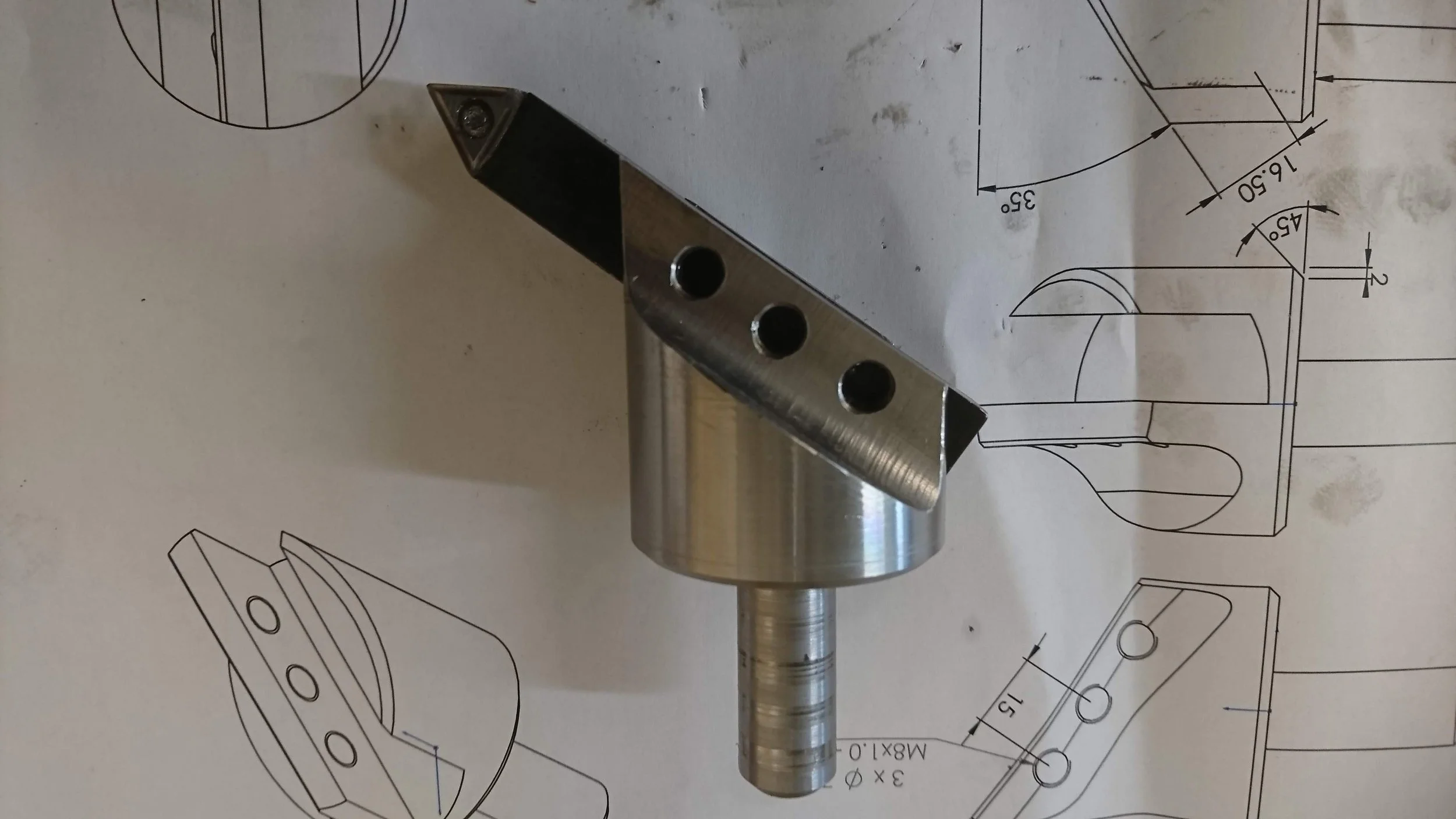

Fly Cutter

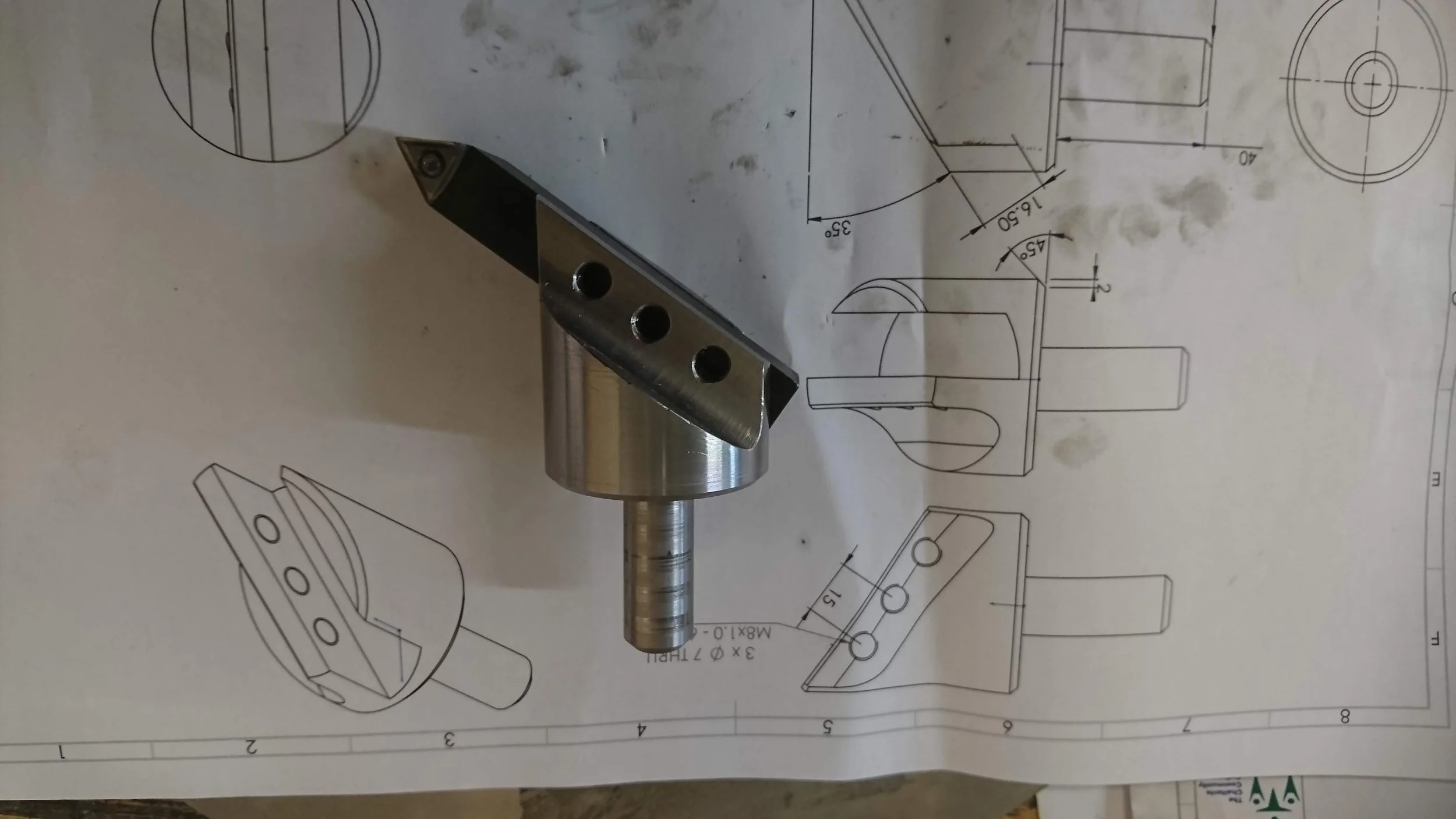

We were in need of a way to machine large flat surfaces on our CNC milling machine, for example on a new fixture plate that I created. In order to save both money and time, I drew up a design in SolidWorks for a fly cutter, utilising an unused lathe tool as the cutting edge. I used a piece of mild steel bar that we had in stock and turned and milled it to the required geometry. This fly cutter was designed to fit in the largest ER25 collet that we had in stock and consequently could be used on either our CNC or fitted into an ER32 collet chuck on our manual machine.

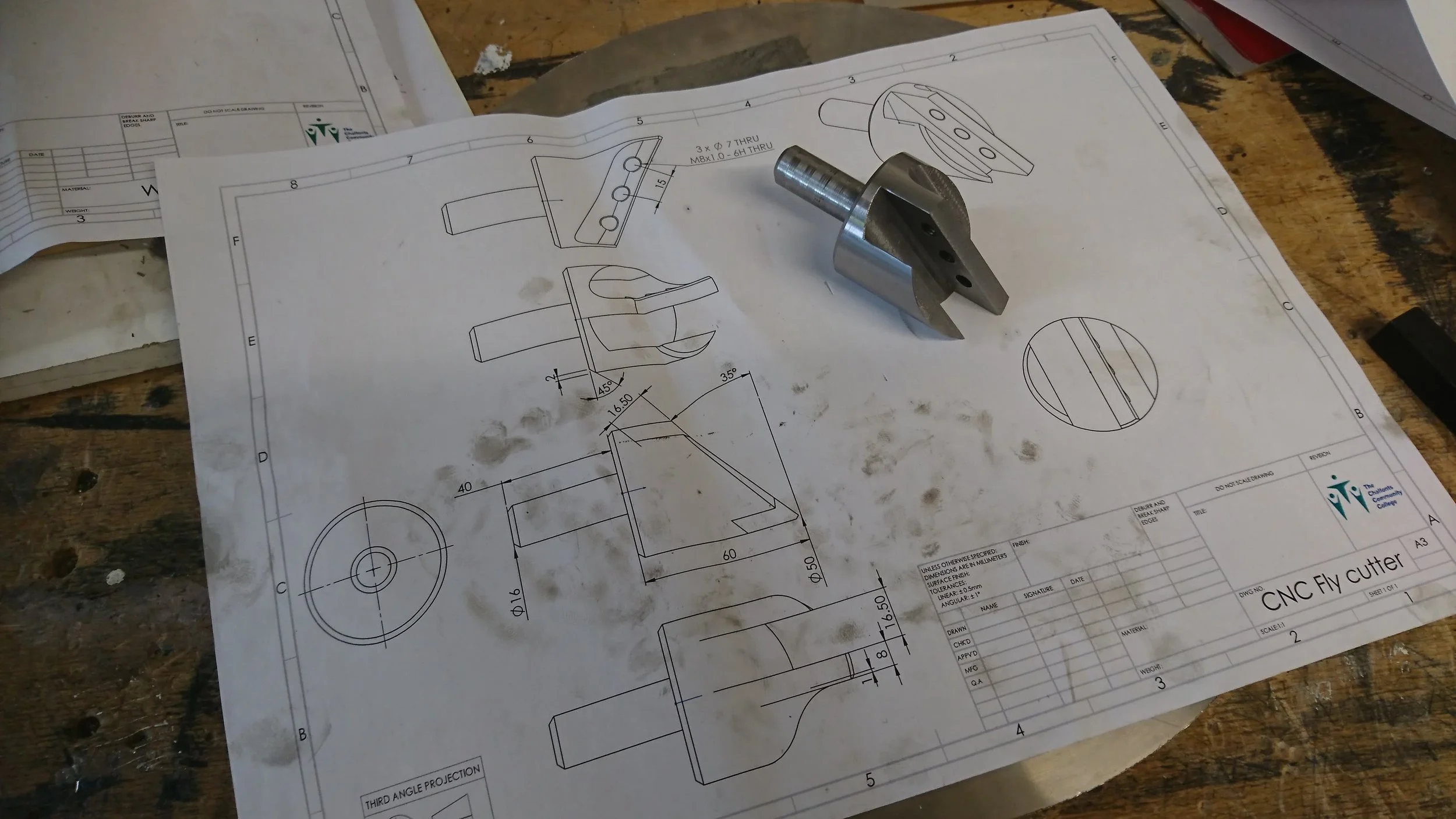

A view of the drawing that I produced and worked to.

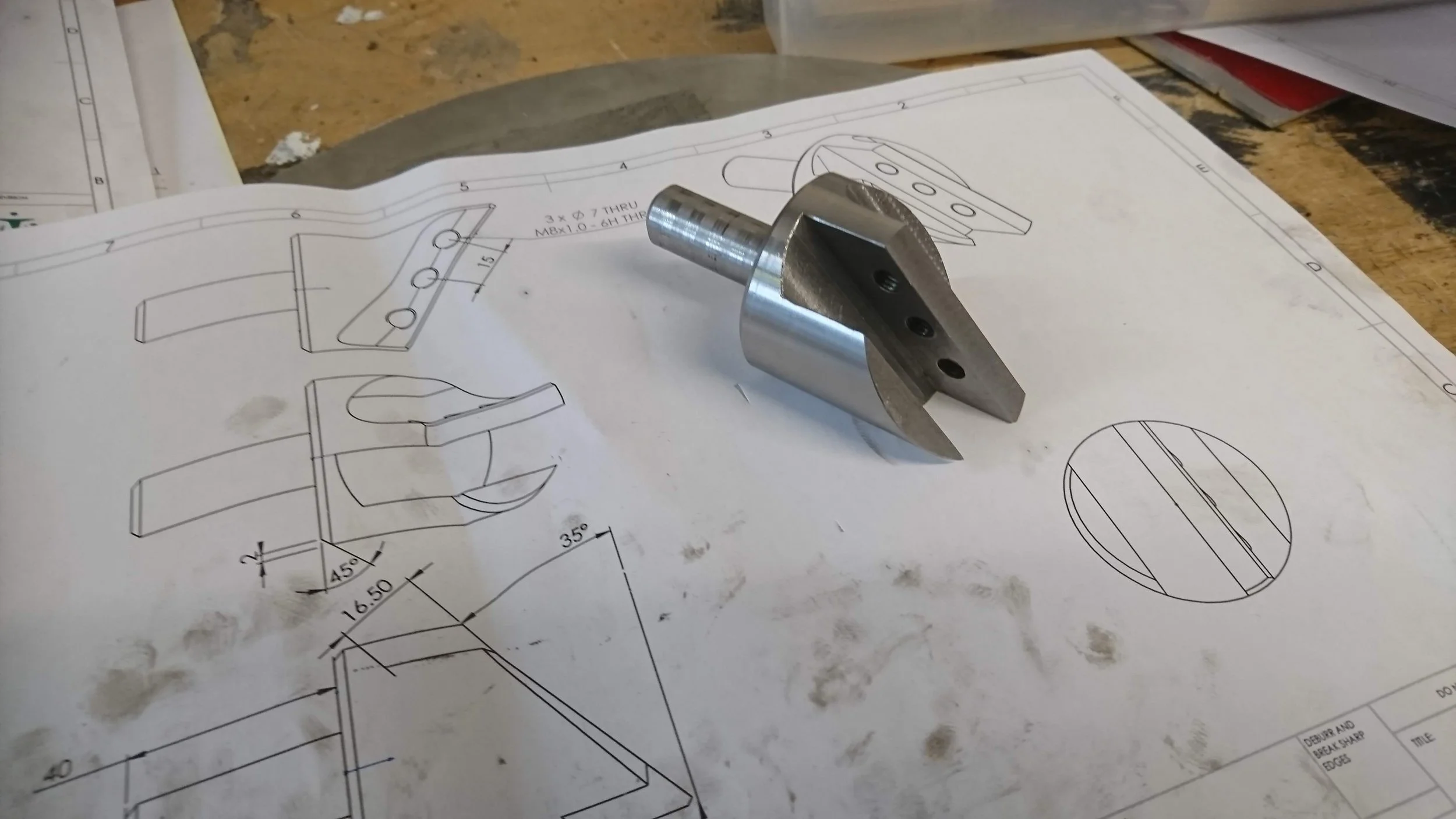

After turning the diameters the milled features needed to be completed. This was done using a square collet block and angle blocks to create the angled features.

The design aimed to keep the cutting surface of the lathe tool running directly in line with the axis of rotation.

The radius was produced using a ball end mill. This was after removing the bulk of the material using regular end mill.

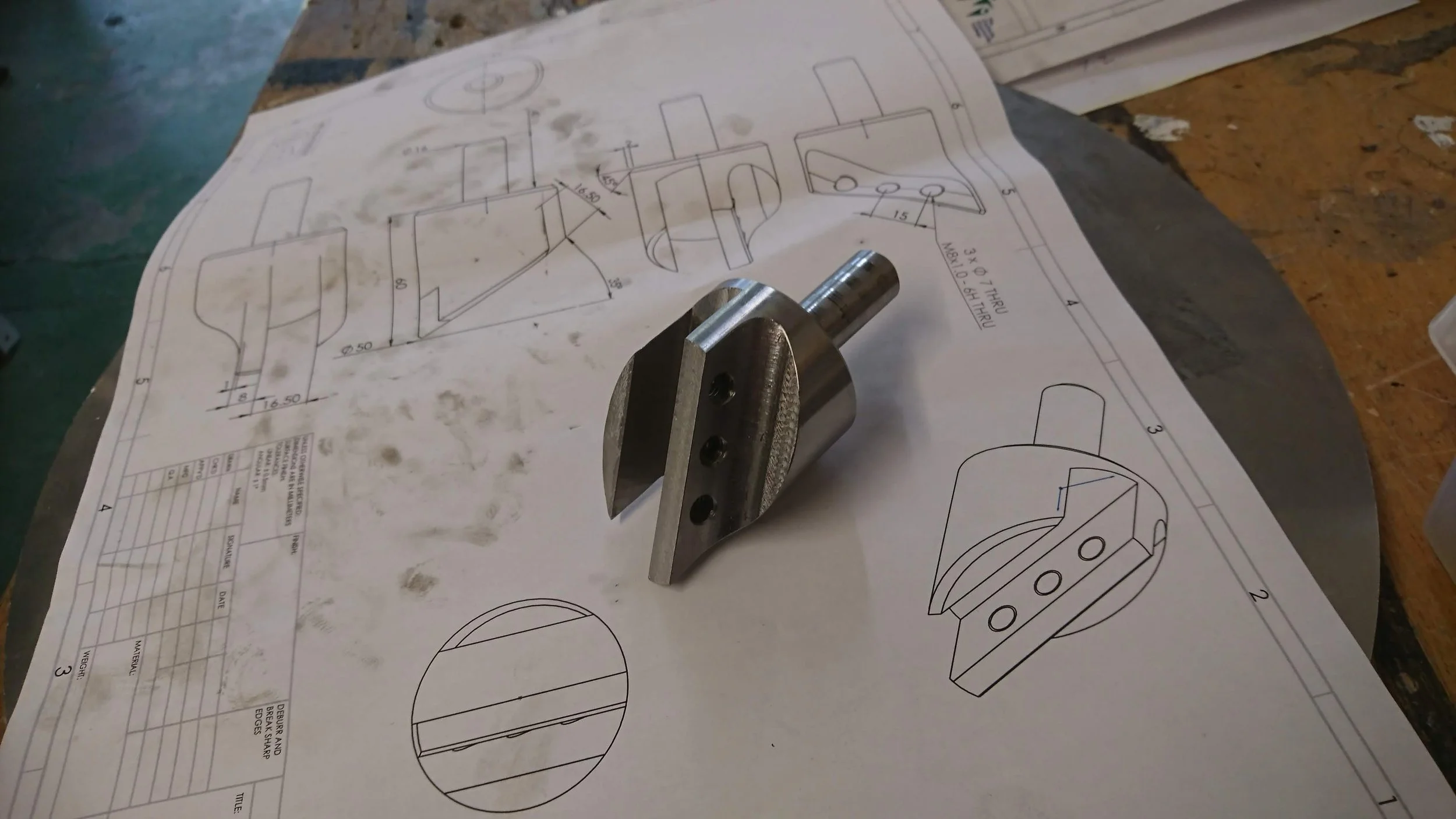

Complete with its lathe tool cutting edge and grub screws.

I was generally happy with the surface finishes on this part.