Laser Cutting

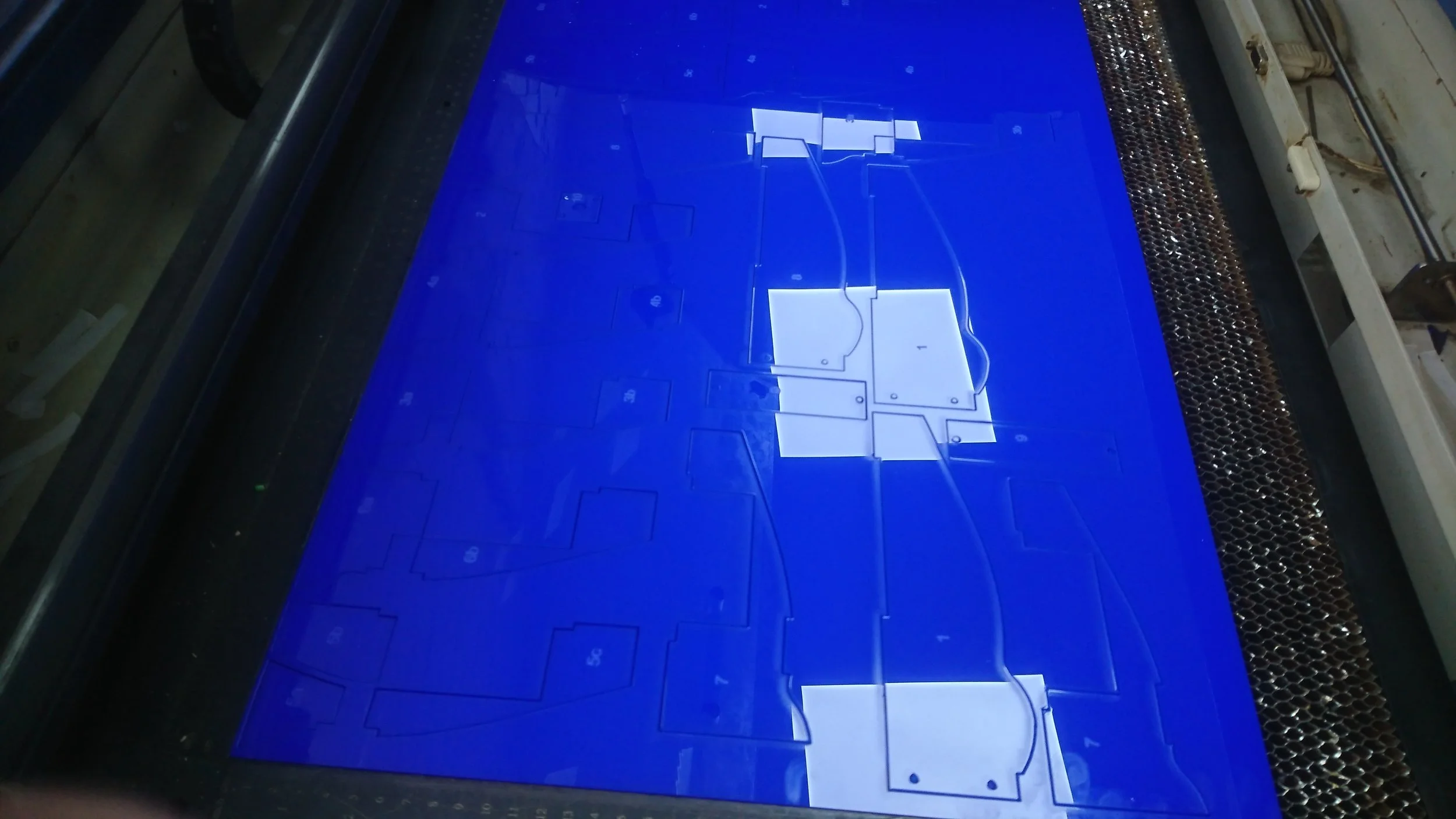

The laser pictured was acquired as a replacement for the 15 year old laser that was in the department when I joined. While the old machine still worked, the laser tube was getting tired and the cutting speeds were very low. I tested whether realigning the mirrors would have an improvement on cutting performance and was able to improve speeds slightly, but ultimately we decided that a new machine was required. When additional equioment funds were offered to departments by the Headmaster, subject to a bidding process, I set out on a mission to research the market, determine the ideal machine for our use case and put together our bid. I researched approximately 20 different machines that would potentially meet our requirements and created an excel spreadsheet of their specifications to enable direct comparisons of features, costings, maintenance and warranty offers etc. and compiled a detailed bid. We were ultimately successful and took delivery of this Boxford BGL690, with a 900mm x 600mm cutting bed and an 80W glass tube CO2 laser tube. Many projects have since been undertaken and it has become one of the most utilised machines in the department.

The laser cutter itself. Capable of cutting a range of organic materials to a depth of up to 9mm or more and engraving in even more materials including stone and glass.

Components of a handheld fan project, cut from acrylic.

Assembled into kits.

This project did not tesselate particularly well. In later years I got exceedingly good at minimising material wastage with quality tessellation.

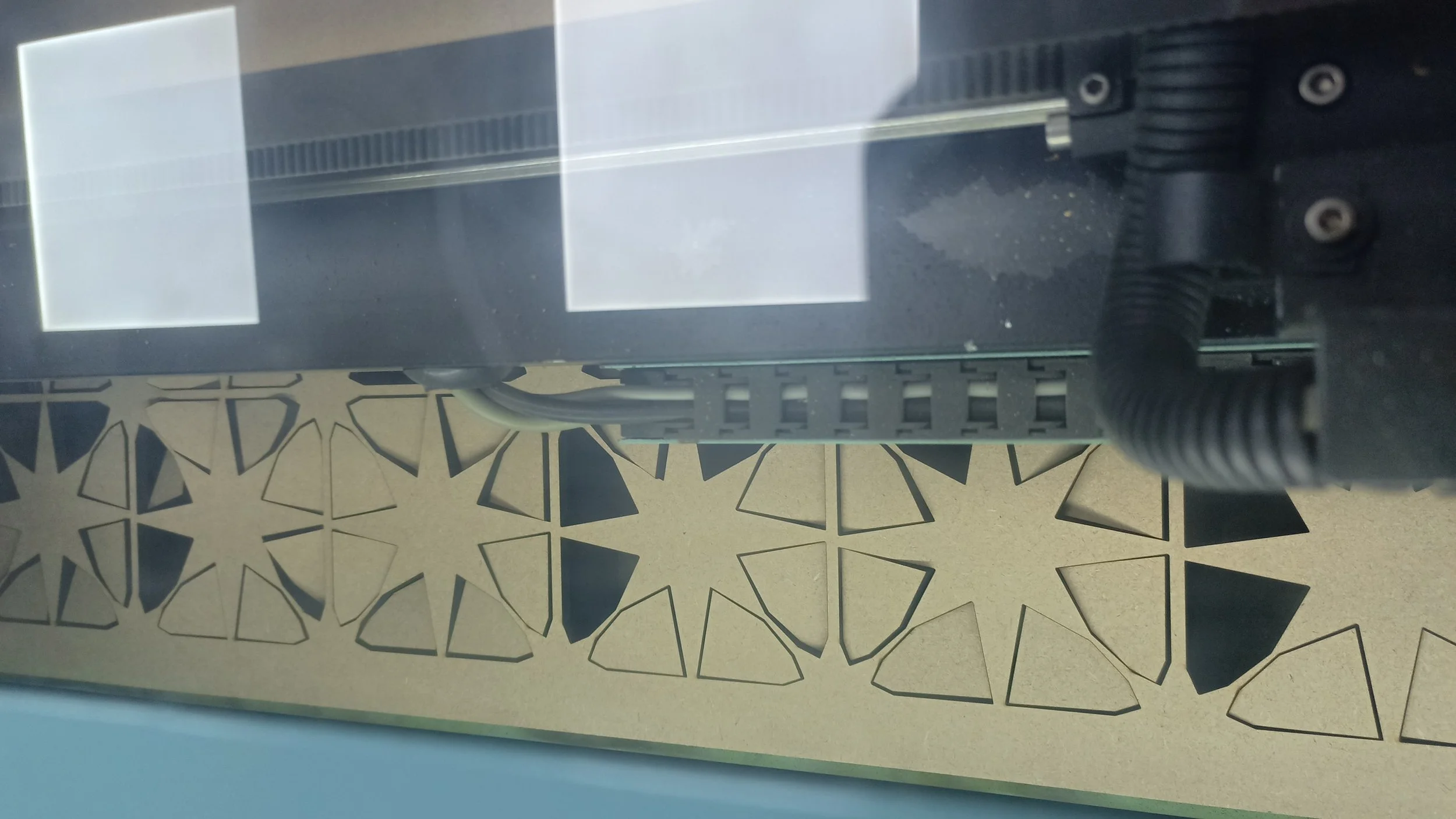

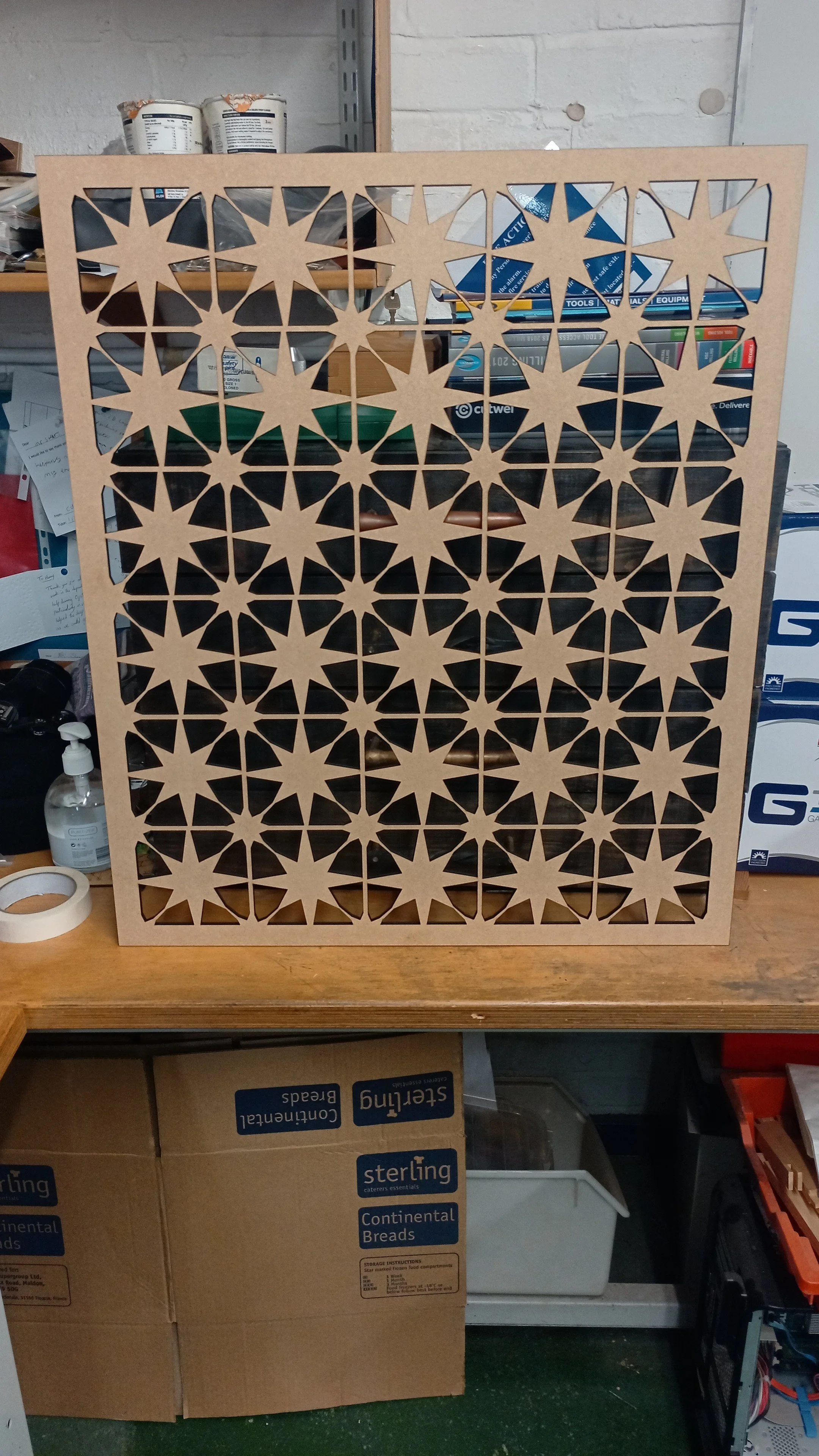

This corridor in my parents' house required a radiator cover. I designed a 3 panel cover, pictured here on the left, with 3 custom panels picking up on the floor tile design.

Cutting in process.

A complete panel.

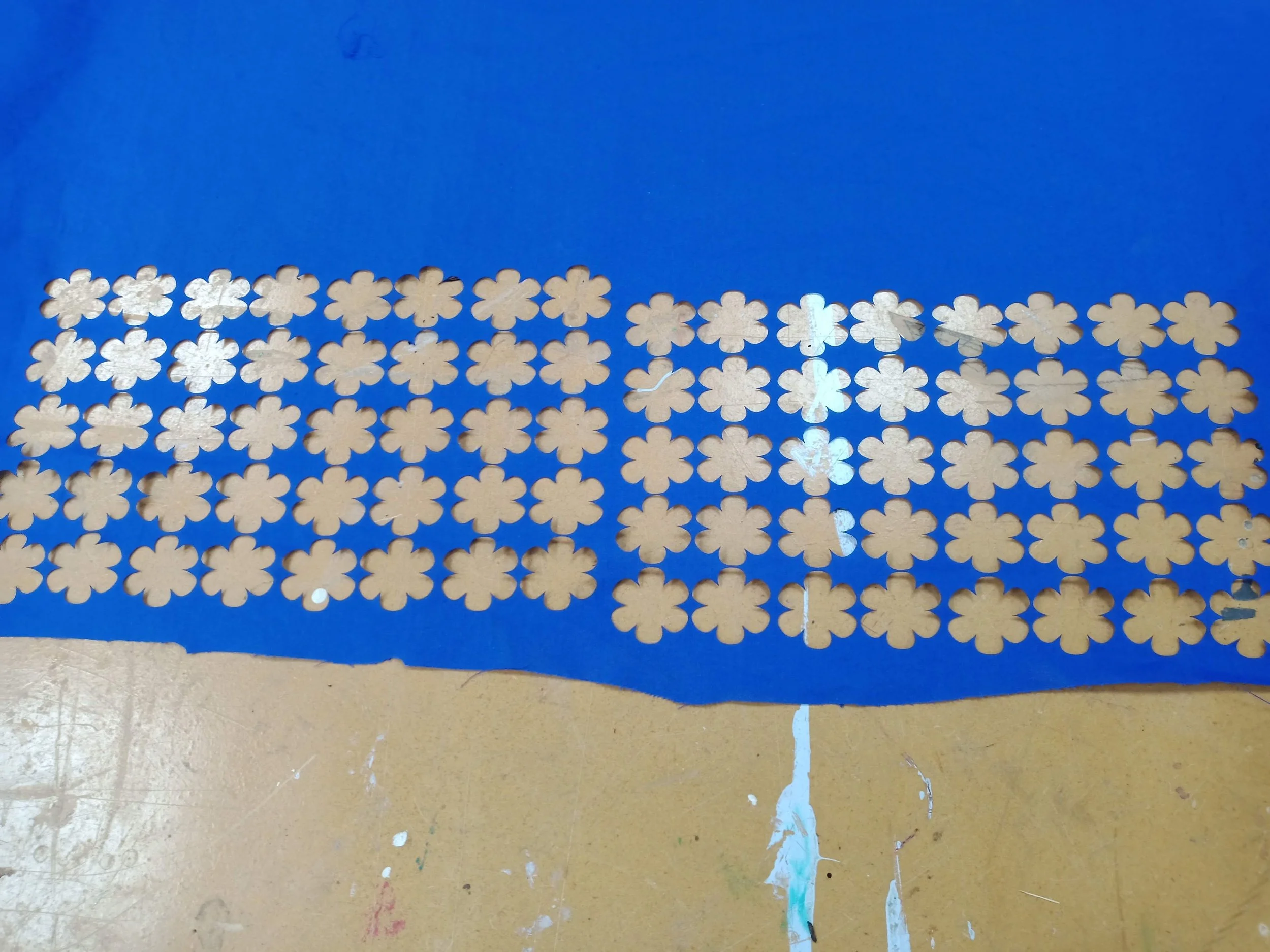

In aid of a textiles project, I cut these flowers from cotton cloth for the student to applique to her design. This was the leftover cloth, showing considerably less wastage than would have occurred with hand cutting.

The process was also considerably faster than cutting by hand. The added advantage in that the heat helps to fix the edges of the cut, minimising the fraying while attaching the pieces.

This jig was constructed to enable cutting slot profiles, at 5 equally spaced angles around this acrylic tube. See 'Student Project Support' for more info.

This project was designed as a table decoration that hung wine glasses.

Holly gift tags, laser engraved and cut.

Christmas tree gift tags cut on behalf of Food Technology. See 'Gifts and Trophies' for more info.

Parts of a Harley Davidson 3D model that I designed as a leaving gift for our headmaster.

The assembled model. See 'Gifts and Trophies' for more info.

A cookbook stand that I designed to be used for gifts for visiting some speakers to the Food Technology department. I manufactured several of these. See 'Gifts and Trophies' for more info.

A laser engraved acrylic panel, which I then edge lit, created this birthday card/gift for our Food Technology teacher. See 'Gifts and Trophies' for more info.