Machinery Repairs

A significant part of my role at The Chalfonts Community College was to maintain and repair machinery and equipment. I had several notable repairs, saving the department tens of thousands of pounds in engineer callout fees and rescuing several machines that might otherwise have been scrapped.

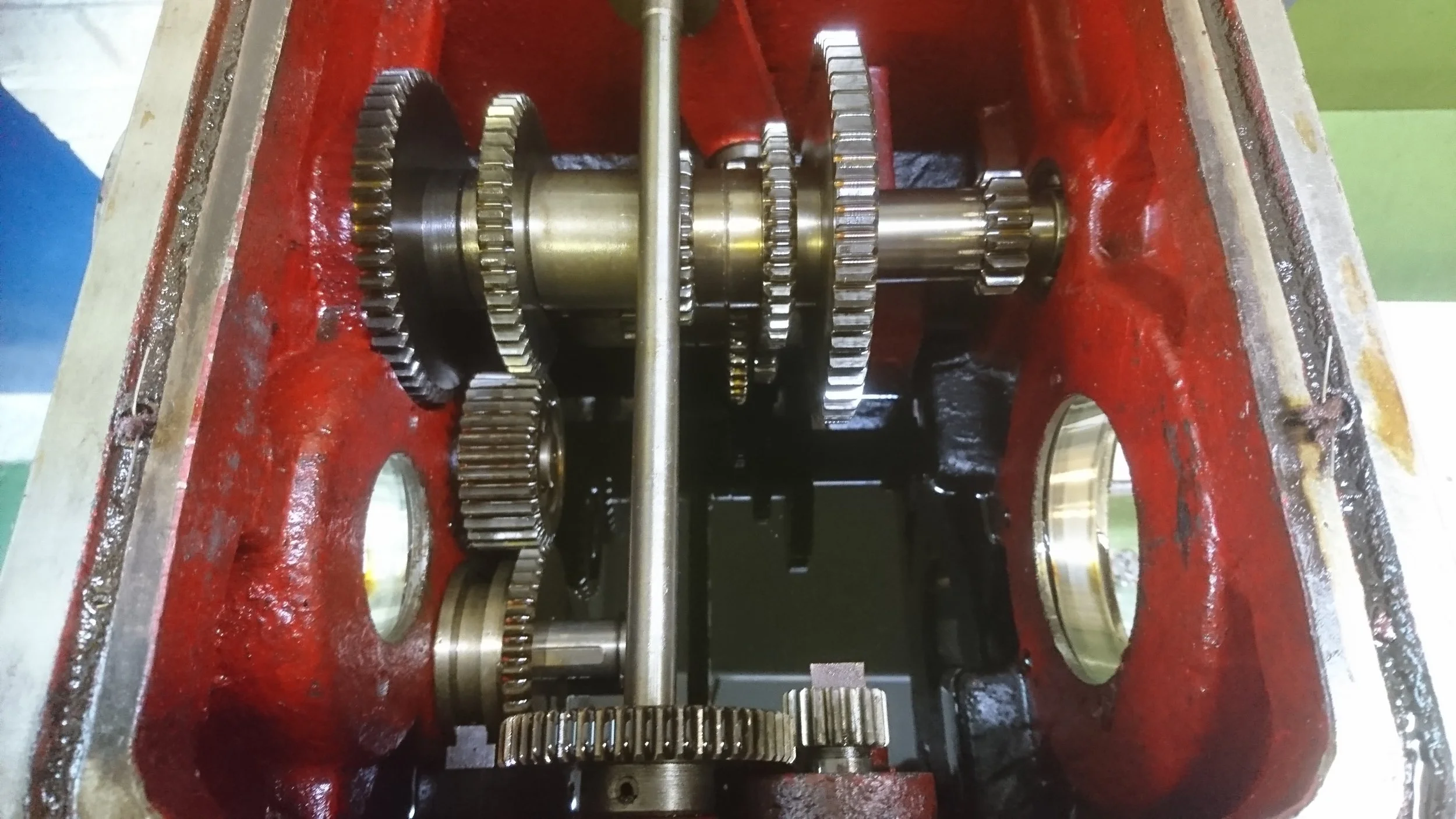

After the emergency brake was pressed while the lathe was running, repairs were required in the gearbox.

It transpired that a couple of keys had sheared, in the process damaging the keyway in one of the gears. Some new keystock and a replacement gear later and the lathe was back up and running.

One of the removed gears. I inspected every gear to check for tooth damage or damage to keyways.

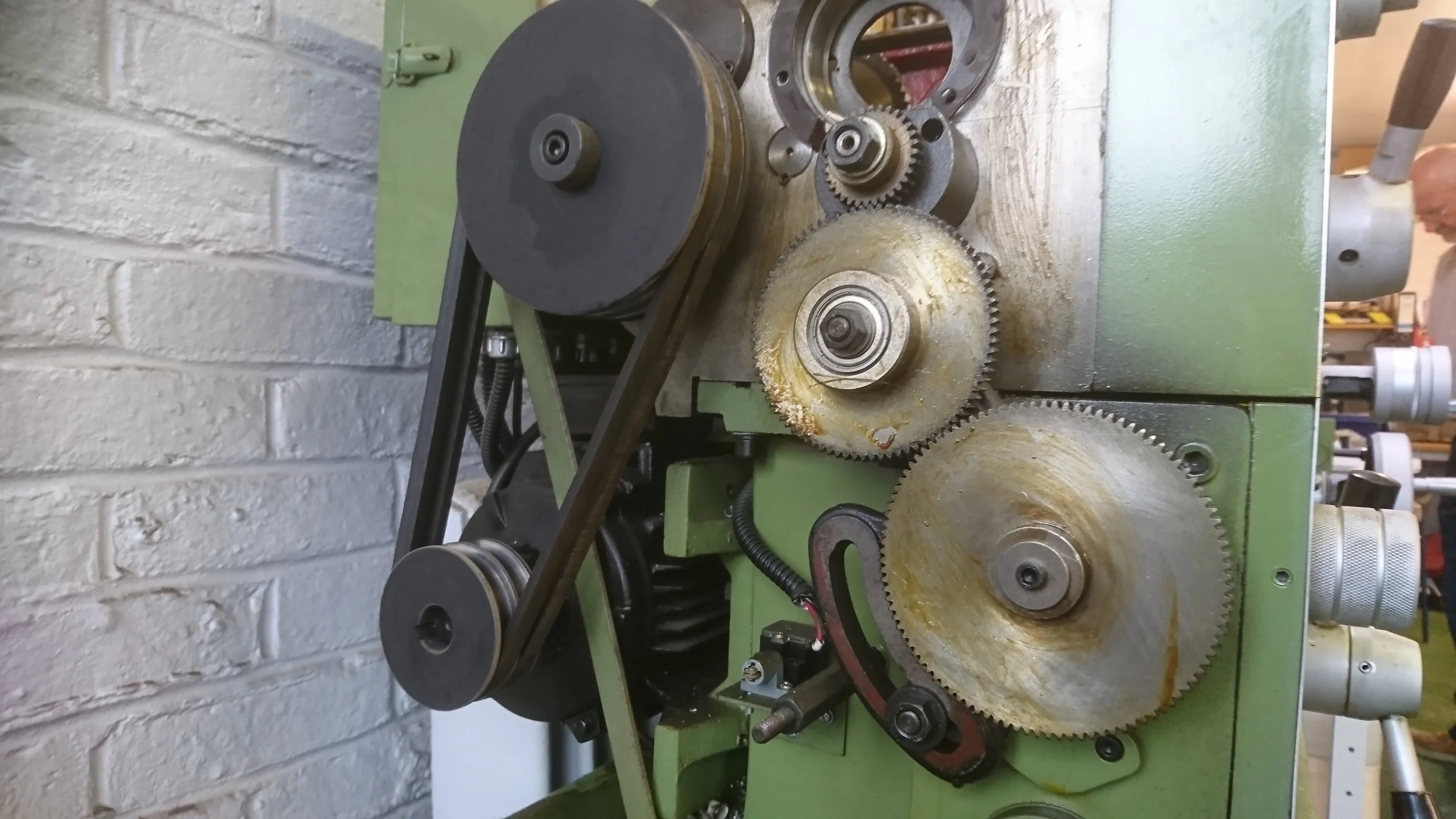

A view of the motor, emergency brake drum and change gears. I was the first person ever to utilise the change gears. This became apparent to me when I realised that ALL the spare change gears were still wrapped in their original waxed brown paper and cosmoline!

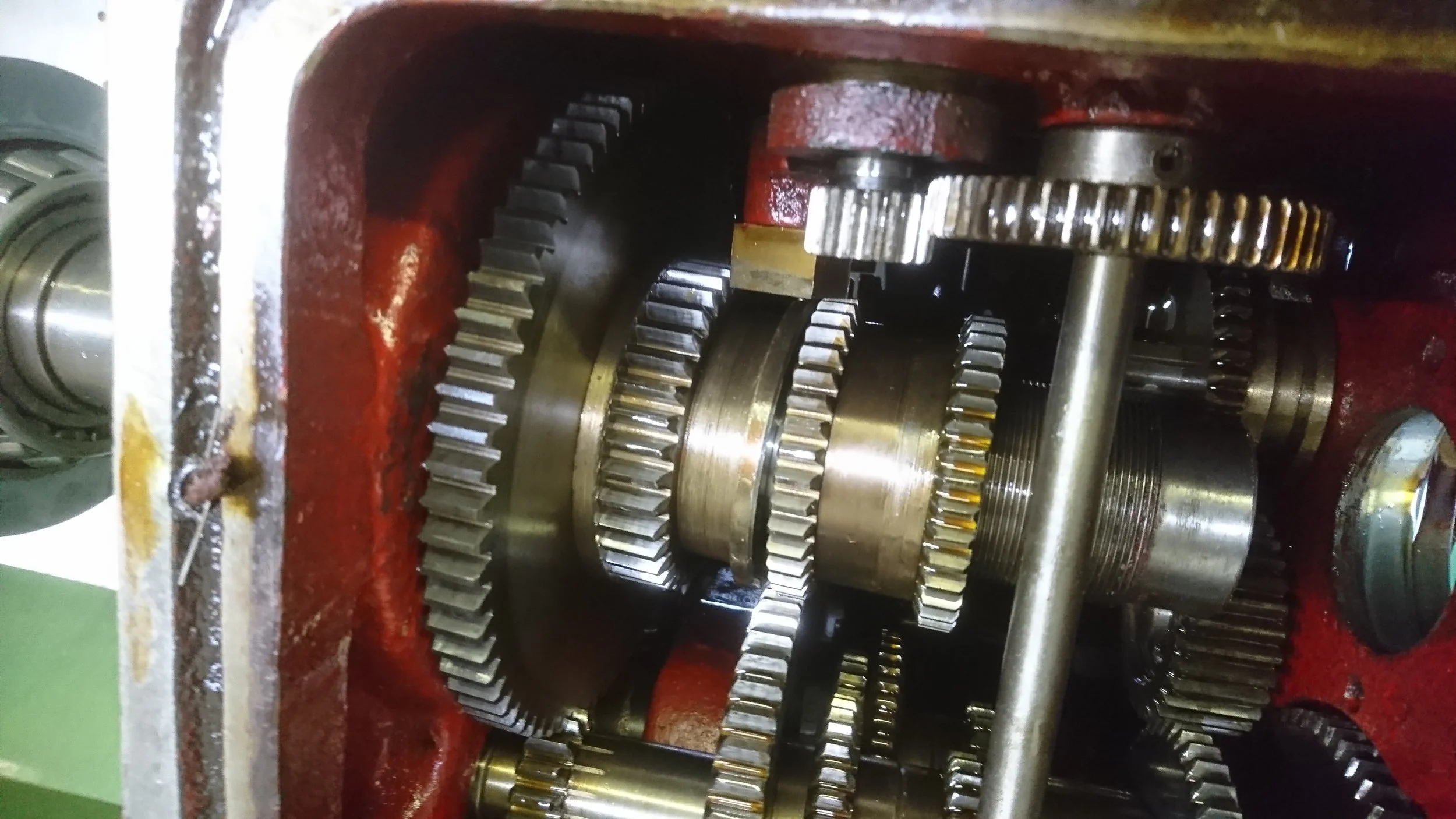

After noticing that the milling machine was producing significant noise under higher cutting loads, I endeavoured to track down the root cause. I began by draining the headstock oil.

These gears are part of the spindle gearing.

This is part of the Z-axis/Quill gearing.

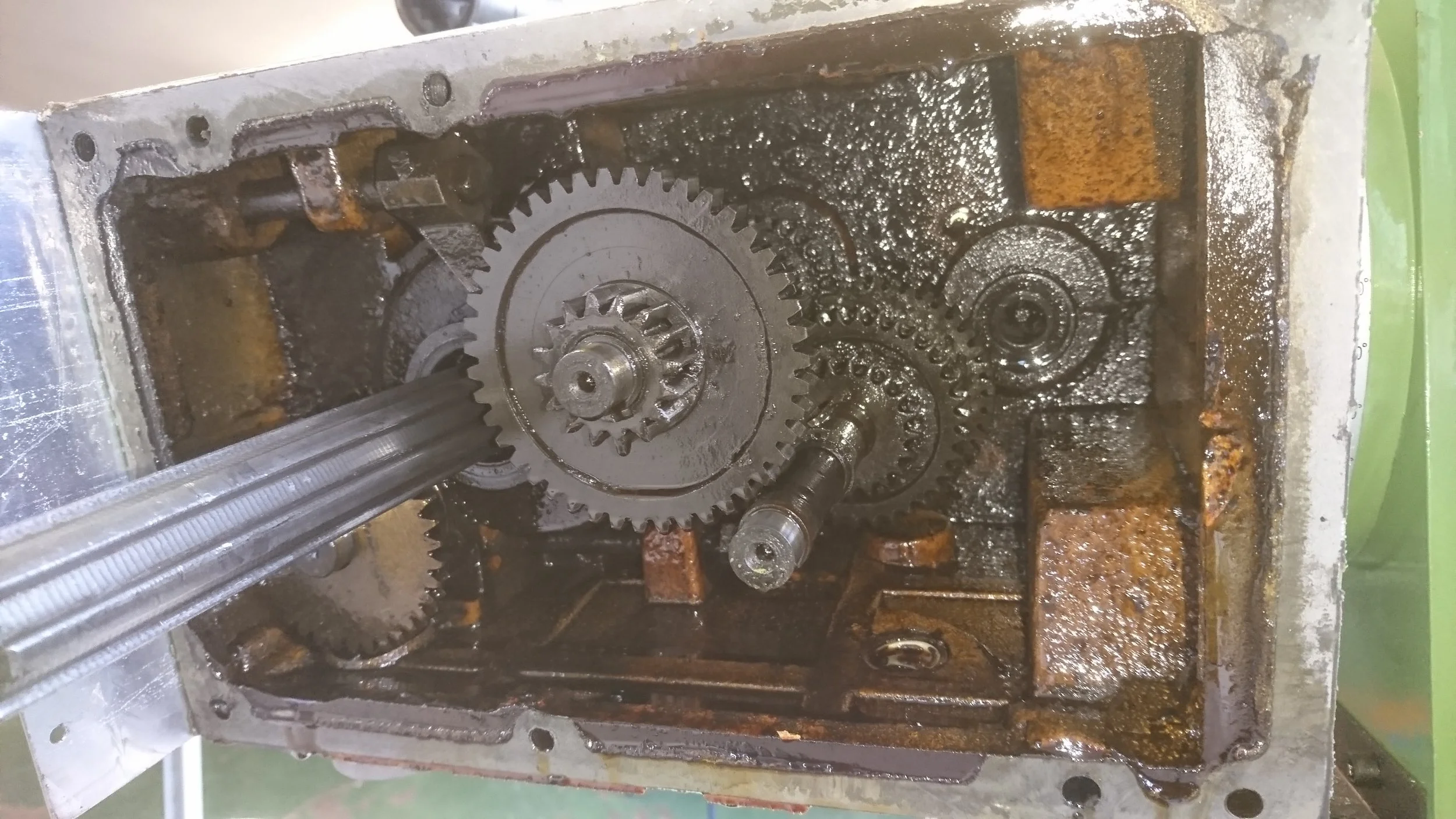

The gearbox oil had clearly not been changed in a while.

After inspecting all the gears and bearings, looking for excess backlash etc. I could not track down a specific issue. Given more time and resource, more could probably have been done to get a proper resolution, but I chose instead to clean, reassemble and limit cutting loads accordingly.

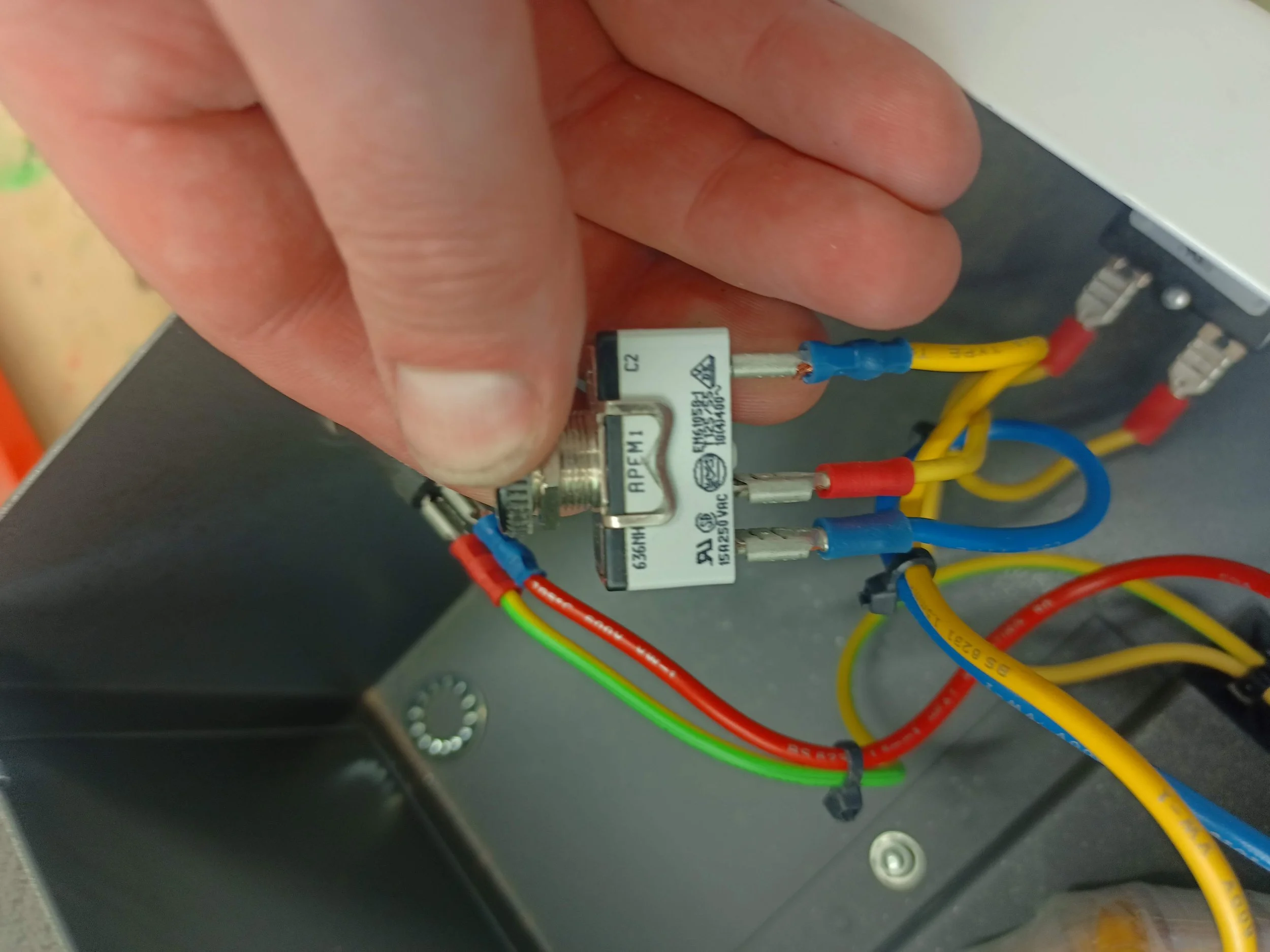

This hot wire strip heater was condemned at the annual machinery inspection due to the High/Low temperature toggle switch plastic actuator having been broken by a student. The recommendation by the external company that did the inspection was to replace the machine (about £400).

I instead found an identical toggle switch from RS Tools, for £1.50 and replaced it, keeping the machine working for years after.

I have had to make several repairs to these scroll saws over the years.

These switches tend to break fairly often. The on button ceases to latch properly. I had to find a supplier of suitable replacement parts as neither the manufacturer, nor the reseller offer spare parts.

These potentiometers also tend to get broken. Often the failure is a mechanical one, where the input shaft is sheared off due to rough handling of the control knob. I sourced suitable replacements with equivalent resistance values and voltage/current ratings.