Non-Ferrous Casting

The Chalfonts Community College is fortunate to have a small aluminium casting furnace. I have used it to produce a number of projects, including the RC car steering axle pictured and have taught casting to numerous classes of students, often culminating in an interactive demonstration. I have used all sorts of different materials to produce plugs, with pine, MDF and 3D printed PLA being some of the common choices. The sand that I used was Bentomix oil-bound casting sand.

A new casting, as it appeared upon withdrawing the cope. Note the chalk on the parting face.

A close up shows the surface finish of the part. One can see details as fine as the layer lines on the 3D printed plug, due to the fine particle size of the bentomix sand used. Note also the charred layer immediately next to the part. This must be discarded while all sand remaining orange can be reused.

A complete casting with the sand removed. Note the sprue and risers that will need to be removed for recycling before the part is ready for use.

And with the cope that it was extracted from.

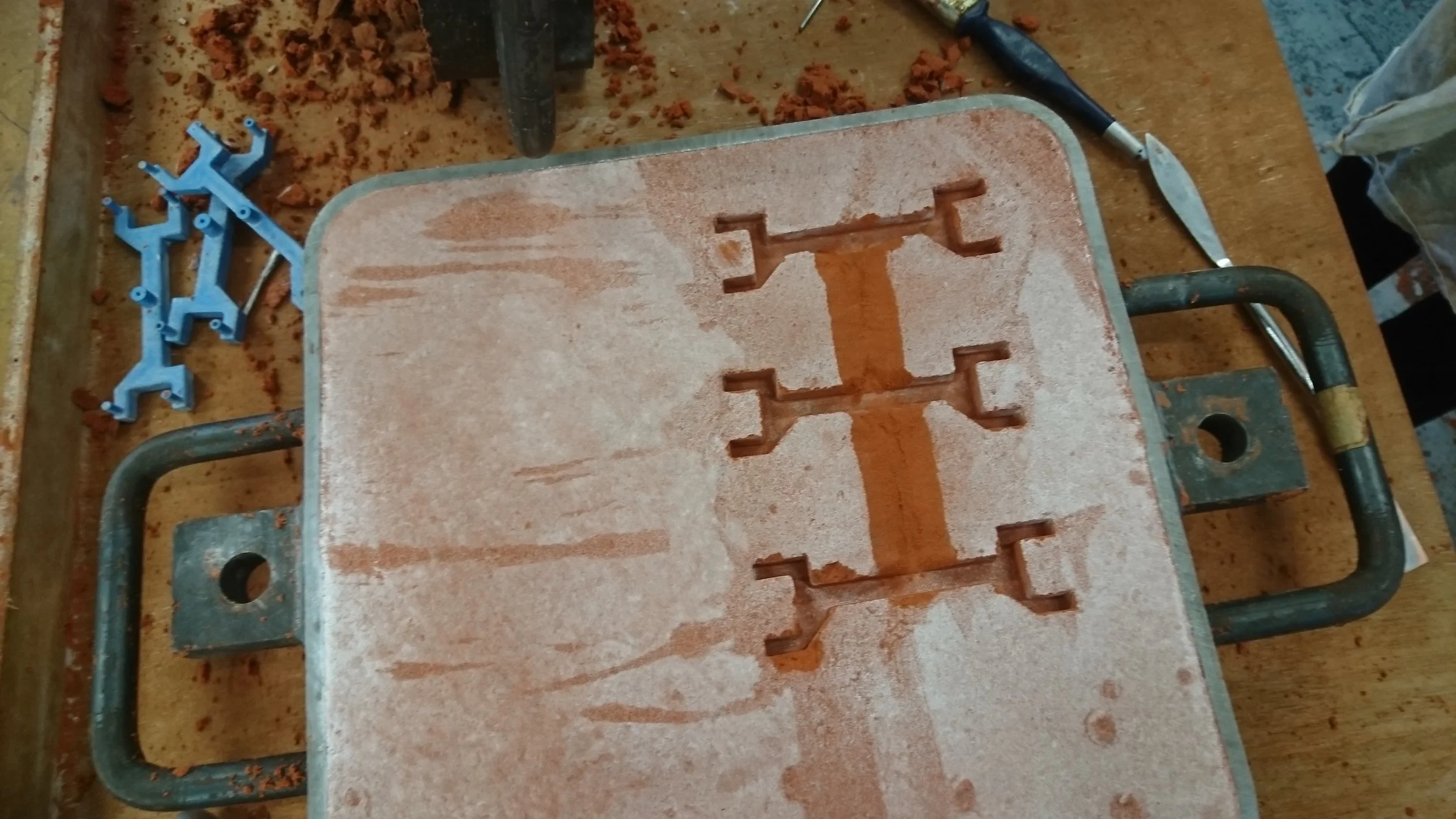

Preparing multiple components for casting in a single mould box. A runner/gate links each component to allow aluminium to flow to each part.

Up close, one can see that the runner/gate was cut by hand.

Risers at each corner ensure gases can escape and sufficient material exists for phase-change contraction at each corner. The sprues in the middle also help ensure that no voids exist in the finished castings.

Here we see both cope and drag, with the 3D printed plugs removed. This just needs assembling, before casting can take place.

A poured casting, next to a couple of mould boxes ready to go.

Overflow on the top of the mould box. A deeper sand funnel may have helped prevent this. The yellow sand on the floor is there to prevent any splashing if spillages do occur when pouring.

The drag is placed upside down with the plug then coated in chalk parting powder. This powder enables extraction of the plug without disturbing the sand that will be packed around it.

The drag is packed with sand and then flipped back over, before more parting powder is applied and the cope installed.