Scheme of Work Development

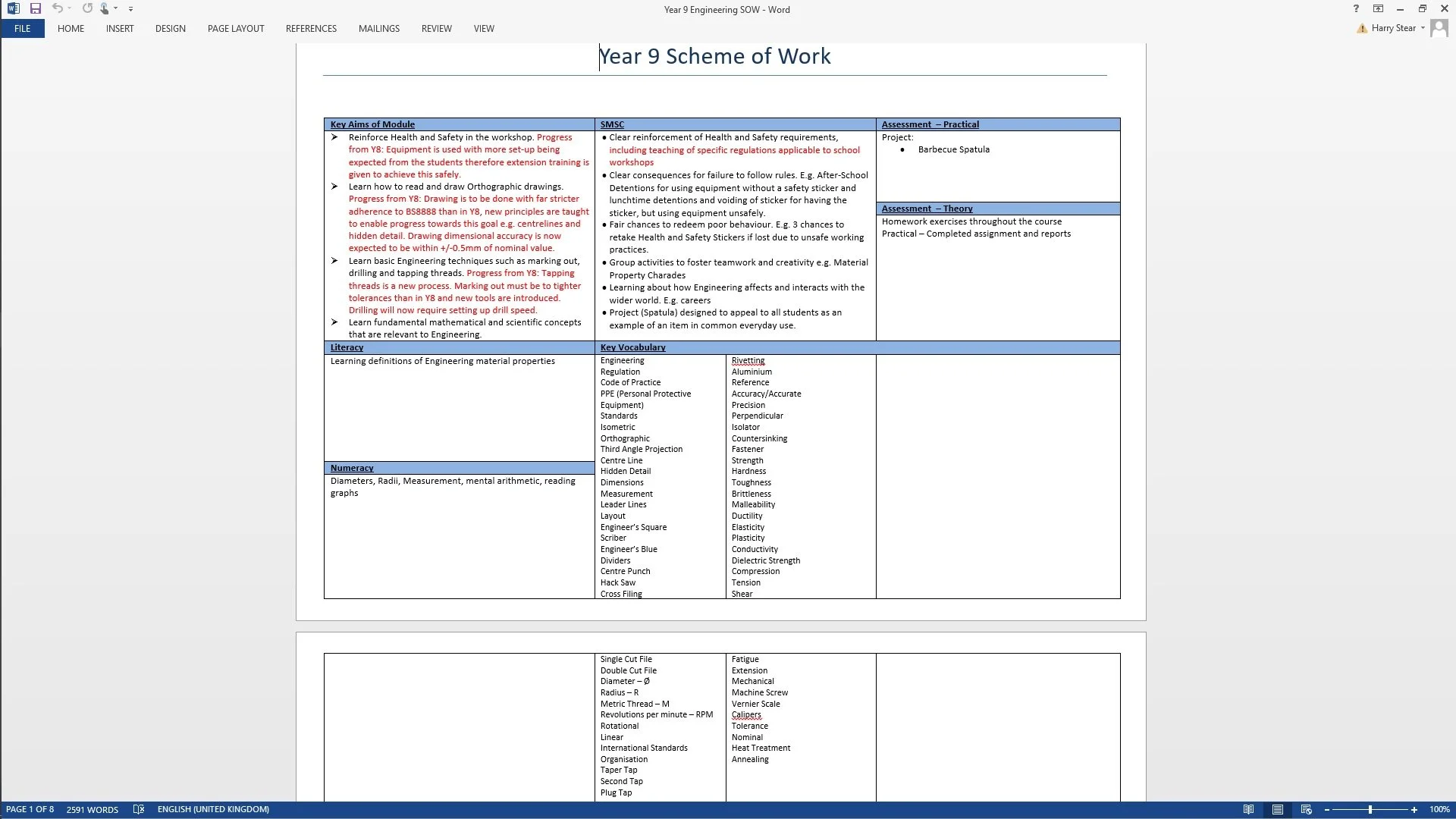

In order to support my department, I helped create schemes of work for engineering courses. I tried to develop courses with a view to setting up foundational knowledge for examination courses in later years. This meant practicing core skills such as reading orthographic drawings, metalworking hands skills, basic materials science and health and safety. I attempted to plan fun lessons with plenty of practical elements and opportunities to test and reinforce knowledge.

Spatula Handle: Skills include reading orthographic drawings, marking out, cutting, filing, drilling, tapping, and bending

The finished spatula demonstrates a number of materials and processes and practices a series of skills required for GCSE level engineering qualifications.

This project was designed to be completed in pairs, with similar processes involved in both the manufacture of the handle and the blade. Assembly is then a joint task, using countersunk machine screws to attach the blade to the tapped threads in the handle.

Wooden grips were designed to be produced using jigs and fixtures both for drilling and belt sanding of the final shape. The grips were then designed to be rivetted to the handle, however testing indicated that even using Oak grips and annealed aluminium rivets, the wood compressed before the head of the solid rivet could be completed properly. A redesign would use solid rivets to attach the blade to the handle and machine screws to attach the two grips.

Click the image to download a copy of the specification for the Y9 Engineering Spatula Project.

Click the image to view the presentation accompanying the Spatula Project scheme of work.

An earlier project for Y9 involved the manufacture of this metal figure, using a range of processes. Drawings for each component taught effective reading of orthographic drawings. An assembly drawing introduced that concept.

The body was gravity die cast in Pewter, using student made MDF moulds, before being drilled and tapped. The head was turned from mild steel on the lathe, before a thread was die cut into the neck. The hat was drilled, cut, and filed from flat bar and MIG welded, with a couple of tack welds, to the head. The legs were made from Aluminium, cut to length and holes drilled, before annealing and bending, mounting to the body was by machine screws. The feet were mild steel, drilled and countersunk for a solid rivet, before case hardening. The arms were cut to length and chamfers filed, before inserting into the body and drilling for a roll pin.