Welding Table

In response to a need for a suitable surface to use for welding, I made use of a large sheet of 6mm steel tread plate that had long been standing in a corner of the workshop gathering dust, ever since it had been retired from its former use as a wheelchair ramp. I drew up a design in SolidWorks for a bench designed to sit on locking castors, its dimensions calculated to fit through the doors in the department such that, if necessary, it could be moved between rooms as required. I presented my design to the head of department and, having agreed a budget for materials, ordered 12m (2 bars) of 100x100x6mm steel equal angle for the main frame and some 25x25x3 equal angle for the shelf from our steel supplier. I cut the required lengths, using an angle grinder to cut the bar into more manageable pieces, then the metal-cutting band saw to cut the necessary lengths and tacked the sections together with the MIG welder. Along the way, I designed and fabricated mounting points for the bottles of argon/argon blend shielding gas for our MIG and TIG welders. I finished the bench by stick welding the bench top to the frame. As we have used the bench I have added storage for TIG filler rods, hooks for cables and other useful attachments as the need has become apparent.

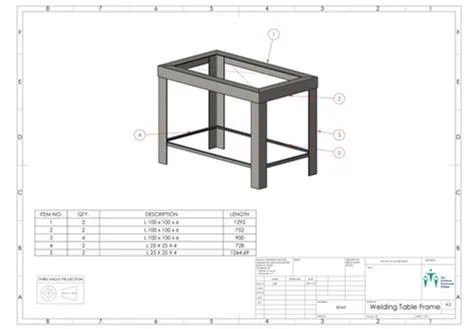

The original design drawing, somewhat simpler than the final article.

Test fitting the frame for the shelf.

Gusseting the mounting points for the castors.

A close-up of an outside corner joint and two lap joints at the intersection of the leg and the benchtop support frame.

Standing on its castors for the first time, bench top trial-fitted.

Adding gas bottle storage and retention to the side of the table. This comprises a strong base shelf, a pair of bent flat bar bottle dividers and a retention strap, also from bent flat bar, but this time bolted to the bench with machine screws, via tapped threads in the frame.

Please excuse the pile of tools and equipment on the bench. This is all equipment that needs to be housed on the bench in a more permanent location.

Two bottles, side by side and securely held.

Looking a little tidier now, complete with shelf for the welders, internal hooks for cables and storage for Tig filler rods.